Working principle of grooving machine

Release time:2025-08-29

Visits:164

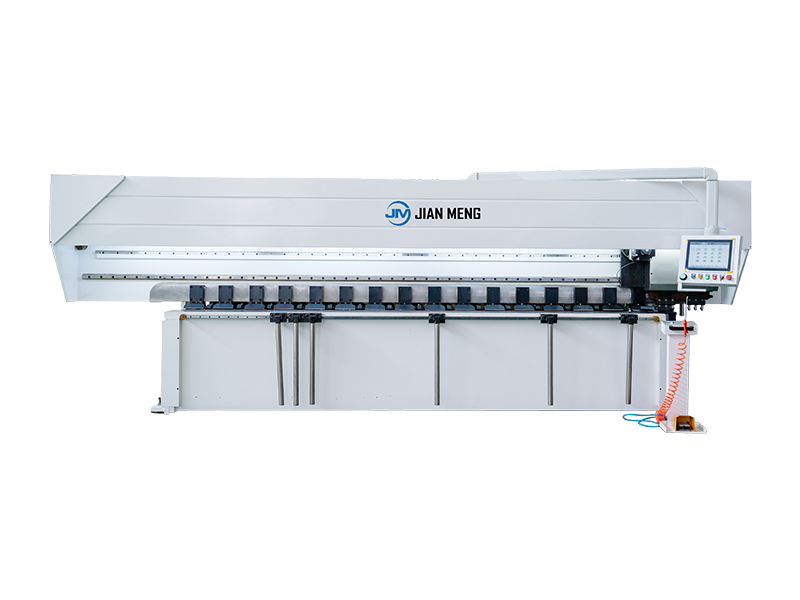

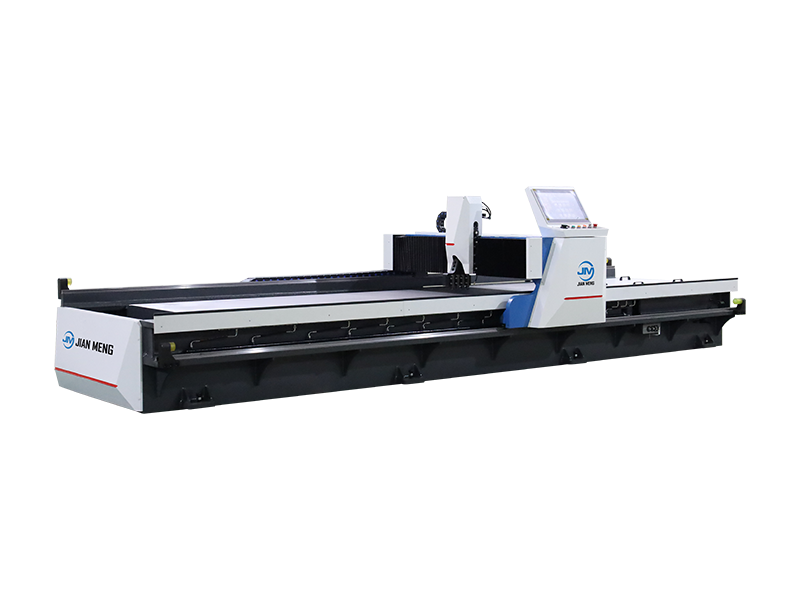

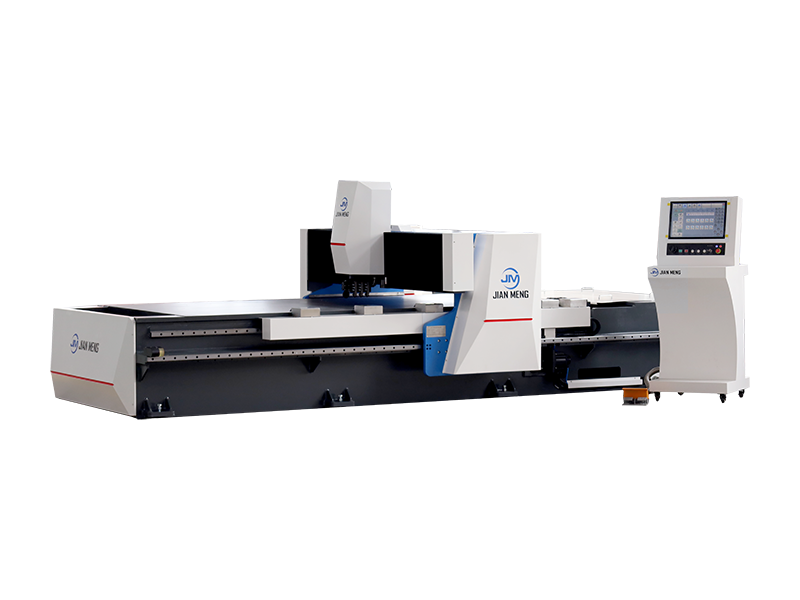

Working principle of grooving machine

1. Mechanical transmission and power part

The grooving machine usually uses a motor as the main power source, and the power output by the motor is transmitted to the tool system and related moving parts such as the worktable through belt transmission, gear transmission, or screw transmission. For example, the motor drives the screw to rotate, and the nut on the screw is connected to the tool holder, allowing the tool holder to move back and forth in a straight line along the guide rail, achieving the cutting action of the tool on the board; At the same time, the workbench can also be moved in the X and Y directions through corresponding transmission mechanisms, in order to perform groove processing on different positions of the sheet metal.

2. Cutting principle of cutting tools

Equipped with specialized planers, the planers come into contact with the surface of the sheet fixed on the worktable during high-speed rotation or linear motion (depending on the specific type of planer, such as the flying blade planer tool rotating for cutting, while the straight blade planer tool performs linear reciprocating cutting). Depending on the sharpness of the tool edge and the appropriate cutting angle, cutting force is applied to gradually remove the material from the sheet, thereby forming the desired groove. During the cutting process, parameters such as cutting speed and feed rate have a significant impact on the quality of the groove and tool life. Reasonable parameter settings can ensure smooth cutting, smooth groove walls, and slow tool wear.

3. Principles of control systems

Most grooving machines are equipped with CNC systems, and operators input relevant parameters of grooving, such as groove length, width, depth, spacing, and coordinate position on the board, into the CNC system through the operation panel. The CNC system will accurately control the motor speed, tool feed motion, and worktable movement based on these instructions, achieving automated and precise groove machining. Moreover, some advanced CNC grooving machines also have automatic detection and alarm functions, which can monitor the wear of cutting tools, whether the cutting force is overloaded, and other abnormal situations in real time. Once problems are found, timely alarms will be issued to prompt operators to handle them, ensuring the safety and quality of the machining process.

In short, with its unique characteristics and scientific working principle, the grooving machine plays an indispensable and important role in many industries such as metal sheet processing, contributing significant strength to improving product quality and production efficiency.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian