Swing Beam Shearing Machine

Product details

Product details

|

|

The Jianmeng QC12K swing beam shearing machine adopts innovative technology and has an electric front angle adjustment function to ensure the accuracy of each cutting.

Our hydraulic swing shearing machine is a popular product in the current market, providing high-quality and cost-effective solutions for cutting full-length and ultra wide sheets.

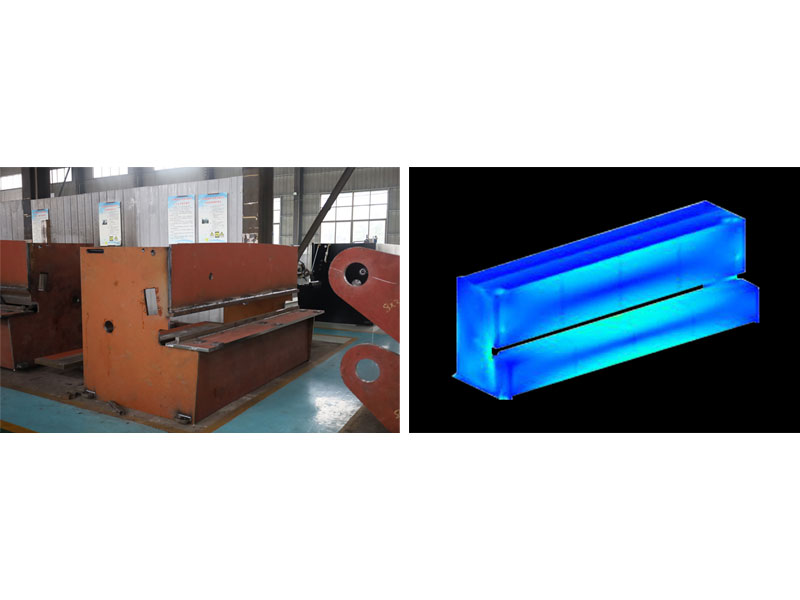

Stress analysis and finite element analysis

The CAE software SOLIDWORKS can be used to analyze the linear static structure, stress, and deformation of the frames of bending machines and laser cutting machines. Therefore, FEA is very meaningful for situations with complex structures, highly complex loads, transient modeling, and combinations of the above factors.

CNC system

ESTUNE21S CNC system

High definition hydraulic display screen

Control ordinary motors and frequency converters

X-axis intelligent positioning

Multi step programming, 40 programs, each with 25 steps

Built in time relay function

One click function switching

Unilateral positioning function

One click backup and restore parameters

Chinese and English

Metric system

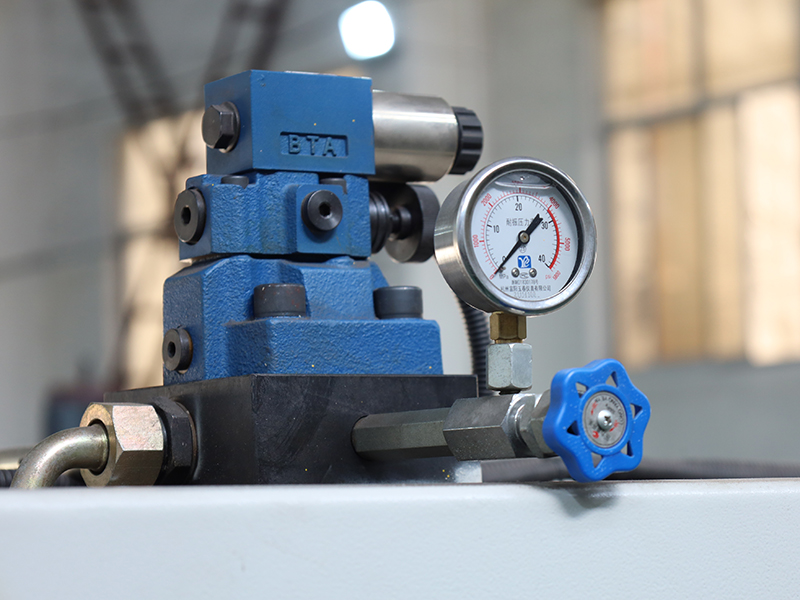

Hydraulic valve group

This machine adopts branded hydraulic valve group.

Due to its oil pressure overload protection function, oil leakage and valve jamming rarely occur.

Real time oil pressure monitoring ensures smooth oil flow and stable operation of equipment.

Feeding Port

Our feed inlet design meets safety standards to ensure the safe and reliable operation of the machine.

Our machine provides Min feed height, which is equal to the thickness of the sheet; Max feed height is equal to the thickness of the sheet plus 20-25 millimeters. The machine is also equipped with height adjustment screws, making it easy for users to customize the feeding height.

Our machines are equipped with front and side guardrails to ensure the safe operation of operators.

Back gauge

One of the important factors in shear capacity is the design and stability of the rear stopper material.

High quality cutting can only be achieved with excellent products, stability, and precise backstepping.

The movement of the rear stop system of the high-speed ball screw is also supported by linear guides, which helps the rear stop to achieve longer lifespan, higher sensitivity, and enhanced resistance to any collision.

Main motor

The use of branded motors increases the service life of the machine and keeps it operating in a low-noise environment.

The power level and installation size of the motor comply with IEC standards, making it very easy to use and maintain.

We have the ability to customize the power and voltage of the machine to meet the specific voltage requirements of the customer's location.

Technical specifications of Swing Beam Shearing Machine

|

Unit |

Cutting thickness mm |

Cutting width mm |

Stroke times min-1 |

Rear material travel mm |

Main motor power kW |

Shear angle ° |

External dimensions mm |

Weight t |

| 4×2000 | 4 | 2000 | 20 | 20-600 | 7.5 | 1°30′ | 2590×1610×1715 | 3.8 |

| 4×2500 | 4 | 2500 | 20 | 20-600 | 7.5 | 1°30′ | 3140×1610×1630 | 4.3 |

| 4×4000 | 4 | 4000 | 8 | 20-600 | 7.5 | 1°30′ | 4640×1640×1830 | 7.5 |

| 6×2000 | 6 | 2000 | 20 | 20-600 | 7.5 | 1°30′ | 2590×1640×1720 | 4.6 |

| 6×2500 | 6 | 2500 | 18 | 20-600 | 7.5 | 1°30′ | 3140×1640×1630 | 5.2 |

| 6×3200 | 6 | 3200 | 14 | 20-600 | 7.5 | 1°30′ | 3840×1640×1630 | 6.3 |

| 6×4000 | 6 | 4000 | 12 | 20-600 | 11 | 1°30′ | 4670×1900×1830 | 9.3 |

| 6×5000 | 6 | 5000 | 7 | 20-800 | 11 | 1°30′ | 5770×2152×2065 | 15.8 |

| 6×6000 | 6 | 6000 | 7 | 20-800 | 15 | 1°30′ | 6800×2300×2360 | 22.2 |

| 8×2500 | 8 | 2500 | 14 | 20-600 | 11 | 1°30′ | 3140×1610×1660 | 5.3 |

| 8×3200 | 8 | 3200 | 10 | 20-600 | 11 | 1°30′ | 3840×1610×1660 | 6.3 |

| 8×4000 | 8 | 4000 | 10 | 20-600 | 11 | 1°30′ | 4700×1910×1830 | 9.5 |

| 8×5000 | 8 | 5000 | 7 | 20-800 | 15 | 1°30′ | 5860×2252×2215 | 18.5 |

| 8×6000 | 8 | 6000 | 6 | 20-800 | 15 | 1°30′ | 6870×2468×2410 | 24.6 |

| 10×2500 | 10 | 2500 | 10 | 20-600 | 15 | 2° | 3400×1690×1800 | 7.8 |

| 10×3200 | 10 | 3200 | 8 | 20-600 | 15 | 1°48′ | 4100×1690×1900 | 9.2 |

| 10×4000 | 10 | 4000 | 8 | 20-800 | 18.5 | 1°54′ | 4850×2152×2090 | 15 |

| 12×2500 | 12 | 2500 | 10 | 20-600 | 15 | 2° | 3400×1690×1800 | 7.8 |

| 12×3200 | 12 | 32000 | 10 | 20-800 | 18.5 | 1°30′ | 4085×2050×2120 | 12 |

| 12×4000 | 12 | 4000 | 8 | 20-800 | 18.5 | 2° | 4870×2250×2150 | 15.3 |

| 12×5000 | 12 | 5000 | 8 | 20-800 | 30 | 2° | 5900×2480×2400 | 22.4 |

| 16×2500 | 16 | 2500 | 8 | 20-800 | 18.5 | 2° | 3435×2050×2130 | 11.5 |

| 16×3200 | 16 | 3200 | 7 | 20-800 | 18.5 | 2° | 4120×2192×2155 | 14.5 |

| 16×4000 | 16 | 4000 | 7 | 25-800 | 30 | 2° | 4900×2300×2315 | 18.6 |

| 20×2500 | 20 | 2500 | 6 | 20-800 | 37 | 2°30′ | 3450×2075×2515 | 15 |

| 20×3200 | 20 | 3200 | 5 | 25-800 | 37 | 2°30′ | 4180×2300×2600 | 19 |

| 20×4000 | 20 | 4000 | 5 | 30-1000 | 37 | 2°30′ | 4950×2388×2760 | 24 |

| 25×2500 | 25 | 2500 | 5 | 40-800 | 45 | 3° | 3460×2300×2696 | 16.8 |

Optional Upgrade of Hydraulic Swing Beam Cutting Machine

FAQ

Product and Industry FAQ

Are you a factory or a trading company?

Are you a factory or a trading company?

We are a manufacturer specializing in sheet metal processing equipment with extensive experience.

We are a manufacturer specializing in sheet metal processing equipment with extensive experience.

Where is your company located?

Where is your company located?

Our company is located in Taixing City, Jiangsu Province, very close to Wuxi Shuofang Airport and Ch

Our company is located in Taixing City, Jiangsu Province, very close to Wuxi Shuofang Airport and Ch

What certifications do your machines have?

What certifications do your machines have?

We hold numerous invention patents and quality certification documents.

We hold numerous invention patents and quality certification documents.

Do you accept OEM customization?

Do you accept OEM customization?

Yes, we accept OEM customization, which includes customizing the appearance, color, configuration

Yes, we accept OEM customization, which includes customizing the appearance, color, configuration

What is your minimum order quantity?

What is your minimum order quantity?

We accept a minimum quantity of one and can customize it via OEM to meet your specific needs.

We accept a minimum quantity of one and can customize it via OEM to meet your specific needs.

What is your delivery time?

What is your delivery time?

Normally, we deliver within 30 days. For non-standard customized machines, it may take a bit long

Normally, we deliver within 30 days. For non-standard customized machines, it may take a bit long

What kind of packaging do you use for your equipment?

What kind of packaging do you use for your equipment?

Due to the large size of our machines, we usually load them directly into containers and secure t

Due to the large size of our machines, we usually load them directly into containers and secure t

Do you provide detailed and professional installation manuals?

Do you provide detailed and professional installation manuals?

Absolutely. Along with the machine, we provide various manuals, operation instructions, precautions,

Absolutely. Along with the machine, we provide various manuals, operation instructions, precautions,

How do you offer after-sales service?

How do you offer after-sales service?

We provide remote assistance from our mechanical engineers to help resolve minor issues during ma

We provide remote assistance from our mechanical engineers to help resolve minor issues during ma

Do you provide training?

Do you provide training?

Yes, you're welcome to send your staff to our factory for hands-on training, where we offer prof

Yes, you're welcome to send your staff to our factory for hands-on training, where we offer prof

More Info? Get In Touch