Press brake

Product details

Product details

Jianmeng has been professionally engaged in the sheet metal machinery manufacturing industry for many years, offering a wide range of models including CNC bending machines, hydraulic press brakes, electro-hydraulic bending machines, twisted shaft bending machines, pure electric servo bending machines, electric press brakes, automatic press brakes, hybrid power bending machines, large tonnage bending machines, sheet metal bending machines, and stainless steel press brakes. Each model demonstrates exceptional performance and unique advantages.

We not only focus on product quality, but also tailor innovative solutions for customers to help improve production efficiency and simplify processes.

The hydraulic-electric hybrid bending machine combines the powerful thrust of hydraulic systems with servo motor drive, achieving a performance blend of high efficiency, precise bending, and low energy consumption. When the equipment is idle or not bending, the servo system shuts down, resulting in lower power consumption while maintaining rapid response and high repeatability accuracy (typically up to ±0.01–0.02 mm), improving production efficiency by 20–30%. The oil-electric hybrid bending machine also features environmental benefits (less hydraulic oil, reduced heat output), low noise levels, and intelligent fault detection, making it highly suitable for mid-to-high-end sheet metal manufacturing and automated production lines.

A high-performance press brake combining hydraulic thrust with servo closed-loop control for precise metal bending.

√ Axis: 4+1, 6+1, 8+1 etc.

√ Capabilities: 50-800 tons

√ Controller: Laimore, DELEM, CYBELEC, ESA

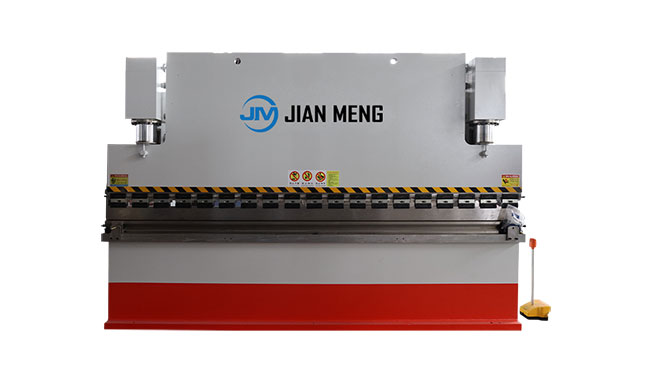

A cost-effective, mechanically synchronized press brake offering robust anti-offset performance for general sheet bending.

√ Axis: 2-8

√ Capabilities: 30-400 tons

√ Controller: ESTUN, DELEM, CYBELEC, ESA

An energy-efficient, low-maintenance press brake using servo drives for ultra-fast response and high positioning accuracy.

√ Axis: 2-9

√ Capabilities: 3-100 tons

√ Controller: ECO, DELEM, CYBELEC, ESA

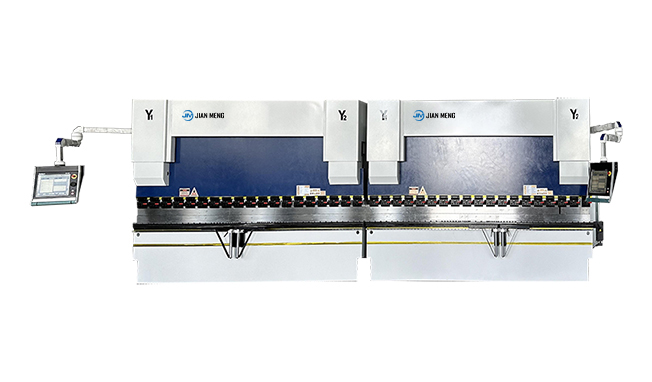

Two (or more) synchronized press brakes working in tandem to bend extra-long panels or distribute tonnage for very large parts.

√ Axis: 4-12

√ Capabilities: 120-1600 tons

√ Controller: Laimore, DELEM, CYBELEC, ESA

Video demonstration

On site case

Application field

Sheet metal fabrication

Elevator manufacturing

Automotive manufacturing

Automotive parts production

Stainless steel kitchen equipment

Home appliance manufacturing

Electrical cabinets and enclosures

Network and telecom cabinets

Metal furniture production

Construction and architectural decoration

Curtain wall and facade panel production

Lighting fixture housing fabrication

HVAC duct and air system fabrication

Shipbuilding and marine parts

Railway and metro train parts

Agricultural machinery fabrication

Heavy machinery and construction equipment

Aerospace ground equipment

Energy and solar power equipment

Storage cabinet and locker manufacturing

Metal doors and frames

Stainless steel decorative products

Enclosures for automation and control systems

Display stands and commercial fixtures

Public transportation vehicle parts

Prototype and product development

Metal work

Why choose Jianmeng

We sell directly to you, eliminating intermediary costs and providing competitive prices

We provide lifelong service to ensure worry free after-sales service for you

We have been deeply involved in the mechanical manufacturing industry for many years and have very rich experience

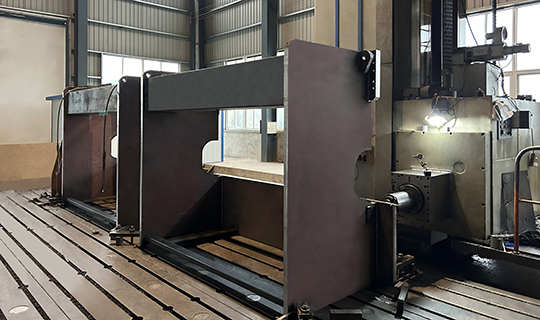

Our equipment framework has undergone heat treatment to ensure accuracy and prevent deformation

Powerful quality control processes ensure that every machine meets strict performance standards

We provide very comprehensive paper and even video materials to give you a comprehensive understanding of Jianmeng equipment

More Info? Get In Touch