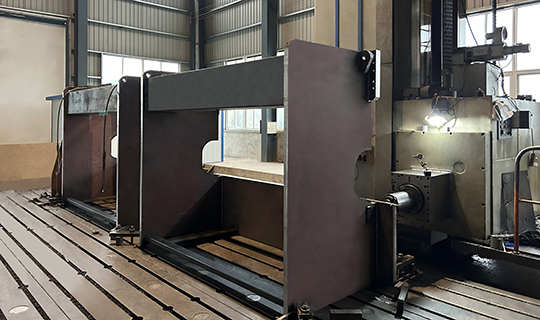

Metal Forming Machine

Product details

Product details

Within JIANMENG's forming technology, we specialize in sheet metal forming, profile bending, component manufacturing, repair, and precision trimming. Our processing is precise, chipless, and cold-formed. JIANMENG Kraftformer tools are customizable for production needs.We offer a range of power cold press forming equipment, available in various models based on forming force, extension length, stroke count, and pressure control.

As a factory focused on forming, shrinking, and stretching machines, we cater to industries such as automotive, aerospace, shipbuilding, high-speed rail, and general sheet metal processing. We design and manufacture machinery and equipment for forming, stamping, and processing sheet metal and profiles.

With a commitment to high-quality products and services, we leverage innovative cold forming technology to shrink or stretch materials. With decades of experience, we are recognized problem solvers in the sheet metal industry. Whether for classic cars or missiles, JIANMENG products ensure precise processing, with our business now serving global markets.

Heavy-duty cold forming solution with deep throat and high-torque servo drive for large or complex sheet metal parts.

√ Throat depth: 665mm

√ SPM: 0-600 times/min

√ Max thickness: 6.0mm (Steel)

Compact, multi-process cold forming machine for precision sheet metal forming and component production.

√ Throat depth: 350mm

√ SPM: 0-400 times/min

√ Max thickness: 2.0mm (Steel)

Powerful, air-driven sheet metal forming solution for curves and precision parts.

√ Throat depth: 400mm

√ SPM: 60-80 times/min

√ Max thickness: 4.0mm (Steel)

Video demonstration

Application field

Forming of aerospace structural parts

Cold forming of aircraft skins

Aircraft skins

Aircraft maintenance

Fuselage parts

Aerospace

Automotive manufacturing and repair

Car fenders

Automotive restoration

Classic car restoration

Bodywork and panel repair

Car door edges

Shipbuilding yachts

Rail transit

Metal craft and fabrication

Metal furniture

Metal exterior wall

Metal decoration

Metal sculpture

Metal art

Metal shaped structure

Metal box closures

Prototyping

Curved metal components

Curved closures

Curved profiles

Door frame contours

Structural corners

Surface finishing

Reshaping irregular formed parts

Decorative edges

Roof craftsmanship

Metal work

Why choose Jianmeng

We sell directly to you, eliminating intermediary costs and providing competitive prices

We provide lifelong service to ensure worry free after-sales service for you

We have been deeply involved in the mechanical manufacturing industry for many years and have very rich experience

Our equipment framework has undergone heat treatment to ensure accuracy and prevent deformation

Powerful quality control processes ensure that every machine meets strict performance standards

We provide very comprehensive paper and even video materials to give you a comprehensive understanding of Jianmeng equipment

More Info? Get In Touch