Deburring machine

Product details

Product details

A deburring machine is a device specifically designed to remove burrs, sharp edges, and burrs generated during the cutting, stamping, milling, and other machining processes of metal parts.

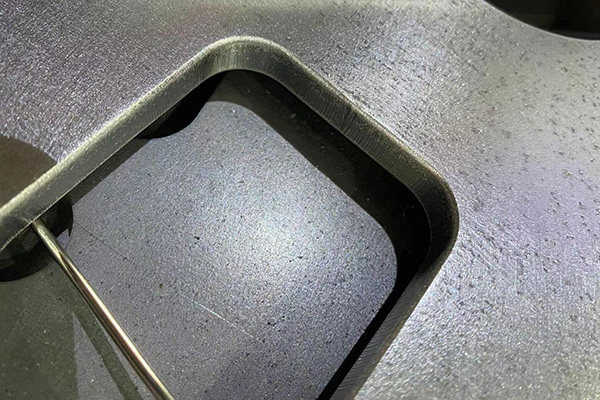

By using mechanical polishing, sanding belts, roller brushes, grinding wheels, and other methods, the edges of the parts can be smoothed to improve the safety, assembly accuracy, and appearance quality of the workpiece.

Metal deburring machines are widely used in industries such as sheet metal processing, automotive manufacturing, electrical cabinets, and mechanical manufacturing, and are important equipment for improving product quality and production efficiency.

Wet dust collector is an efficient dust collection device designed specifically for deburring machines. It is mainly used to remove dust, burrs, residues, sparks, and other pollutants generated during metal processing. Compared with traditional dry dust collection systems, wet dust collectors treat dust through water filtration to prevent dust combustion or explosion, thereby improving workplace safety and complying with environmental standards.

The XDP-RP series is a combination model of dry wide-belt + roller-brush deburring machine that completes deburring and chamfering in a single pass to improve their surface quality.

√ Function:Deburring + Edge rounding

√ Adsorption method: Vacuum

√ Available widths: 450-1600 mm

√ Edge rounding rage: R0.1-0.5 mm

The XDP-RR series is heavy-duty metal sander for thick parts, heavy burr and oxide scale removal, with powerful cutting and optional wet dust collection..

√ Function:Deburring + Surface finishing

√ Available widths: 600-1600 mm

√ Processing thickness: 1-100 mm

The XDP-MRP series is engineered for carbon-steel surface treatment, using wide sand belts and universal roller brushes to deburr, chamfer, and create brushed finishes.

√ Function:Deburring + Edge rounding

√ Adsorption method: Magnetic

√ Available widths: 450-1600 mm

√ Edge rounding rage: R0.1-1.0 mm

The XDP-RPR series combines sand-belt grinding, roller-brush chamfering and vacuum adsorption to efficiently deburr, chamfer and produce uniform brushed finishes; a high-damping rubber conveyor plus vacuum fan ensure stable high-speed handling, with adjustable parameters and selectable abrasives.

√ Function:Deburring + Edge rounding + Brushing

√ Adsorption method: Vacuum

√ Available widths: 450-1600 mm

√ Edge rounding rage: R0.1-0.5 mm

The XDP-MRPR series combines sand-belt grinding, roller-brush chamfering and vacuum adsorption to efficiently deburr, chamfer and produce uniform brushed finishes; a high-damping heat-resistant conveyor plus magnetic platform ensure stable high-speed handling.abrasives.

√ Function:Deburring + Edge rounding + Brushing

√ Adsorption method: Magnetic

√ Available widths: 450-1600 mm

√ Edge rounding rage: R0.1-0.5 mm

The XDP-RPRT series— RPR with an added polishing station, delivering end-to-end processing from deburring to deliver one-step polishing finishing.

√ Function:Deburring + Edge rounding + Brushing +Polishing

√ Adsorption method: Vacuum

√ Available widths: 450-1600 mm

√ Processing thickness: 0.5-100 mm

The XDP-MRPRT series— MRPR with an added polishing station, delivering end-to-end processing from deburring to deliver one-step polishing finishing.

√ Function:Deburring + Edge rounding + Brushing +Polishing

√ Adsorption method: Magnetic

√ Available widths: 450-1600 mm

√ Processing thickness: 0.5-100 mm

The XDP-RRT series is flat-surface dry brushing machine for fine texture refinement and pre-treatment finishing.

√ Function:Deburring + Brushing +Polishing

√ Available widths: 600-1600 mm

√ Processing thickness: 0.5-100 mm

The XDP-WRR series is wet-type brushing (water-finish) that removes heat and creates finer textures, ideal for aluminum, copper and other non-ferrous metals.

√ Function:Deburring + Surface finishing +Polishing

√ Available widths: 600-1600 mm

√ Processing thickness: 0.5-100 mm

The XDP-WDC series wet dust collector with gas-liquid separation that efficiently captures dust while providing cooling and purification for finishing lines.

√ Power:3.0/5.5/7.5 kW

√ Total pressure: 1343/1723/3200 Pa

√ Air inlet: φ200/300/400 mm

√ Purification efficiency: ≥95%

The XDP-SD series is a manual machine for side-edge deburring, efficiently removing burrs and sharp edges on metal workpieces.

√ Function:Deburring + Edge rounding +Grinding

√ Processing thickness: 0.5-3 mm

Video demonstration

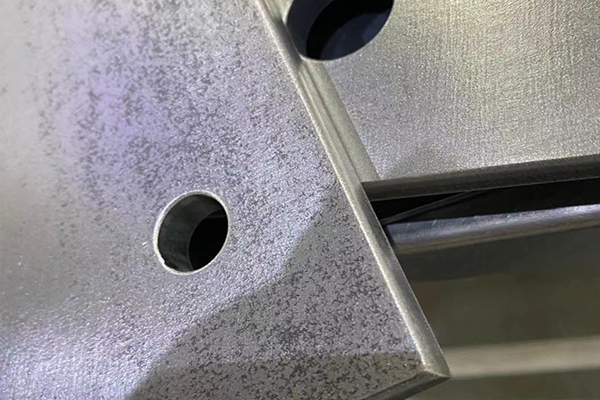

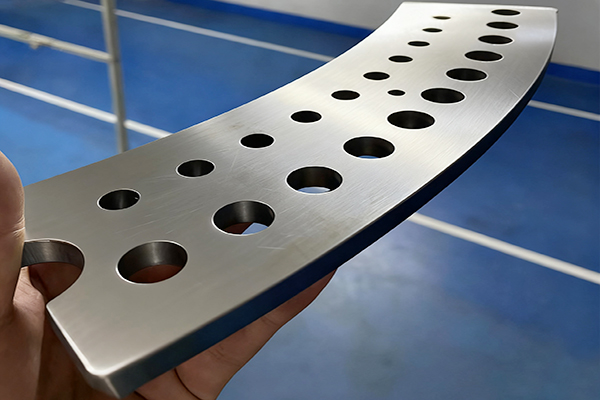

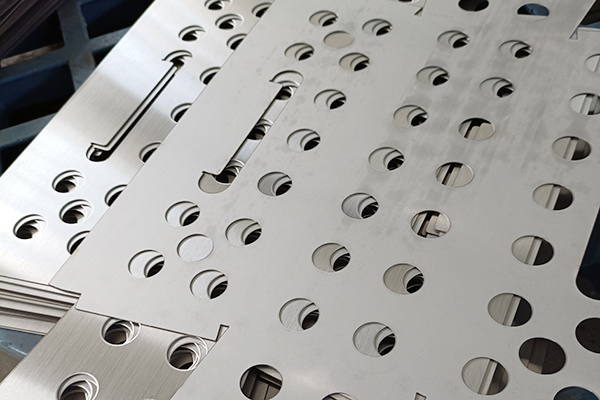

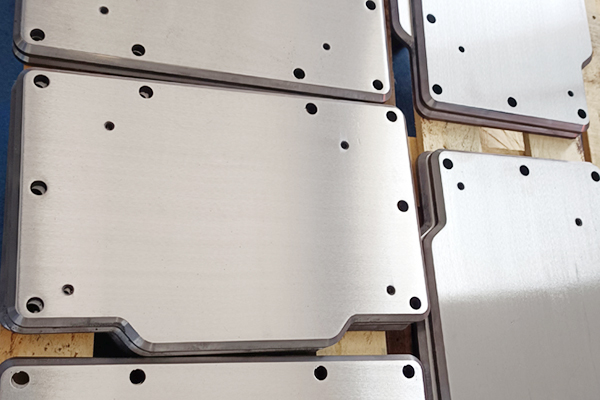

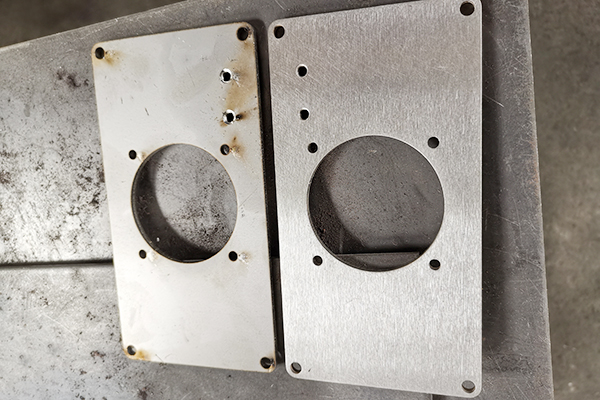

On site case

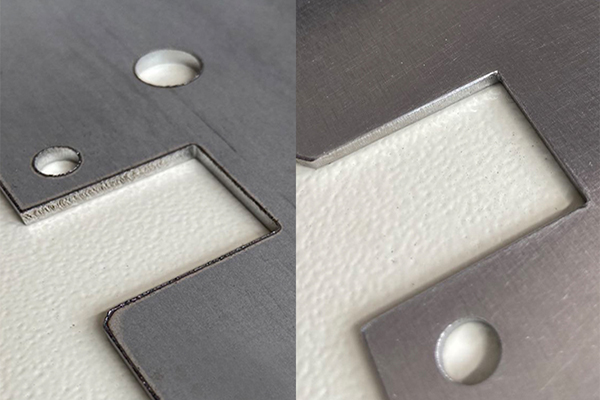

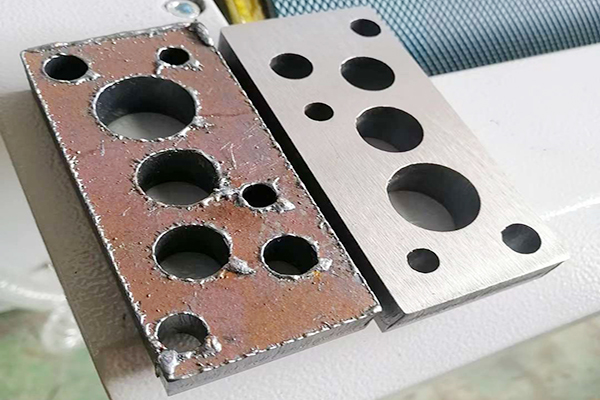

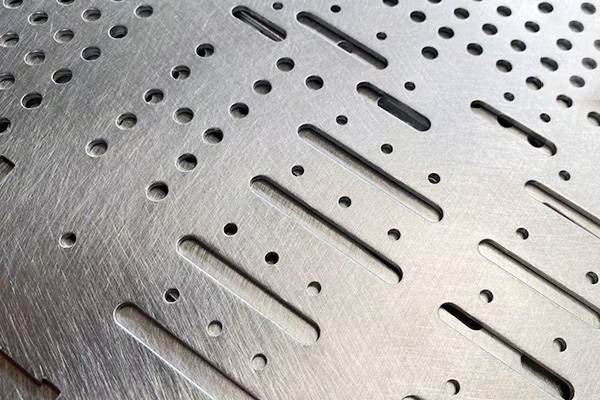

Product effect

Application field

Aerospace industry

Railway & Metro industry

Automotive industry

Metal furniture

Home Appliances & Kitchen equipment

Kitchen equipment polishing

Elevator & Lift manufacturing

Elevator panel finishing

Electronics & Electrical cabinets

Sheet metal processing

Sheet metal fabrication

Laser-cut parts

Laser-cut part polishing

laser cutting workshops

Fabrication shops

Hardware & Machining

Stainless steel

Stainless steel products

Stainless steel finishing

Steel service centers

Small metal parts

Mild steel parts

Aluminum deburring

Aluminum and copper polishing

Decorative metal polishing

Industrial polishing for flat sheets

Surface finishing

Why choose Jianmeng

We sell directly to you, eliminating intermediary costs and providing competitive prices

We provide lifelong service to ensure worry free after-sales service for you

We have been deeply involved in the mechanical manufacturing industry for many years and have very rich experience

A high-rigidity welded frame with precision assembly, providing vibration resistance and fatigue durability

Powerful quality control processes ensure that every machine meets strict performance standards

We provide very comprehensive paper and even video materials to give you a comprehensive understanding of Jianmeng equipment

More Info? Get In Touch