CNC V grooving machine

Product details

Product details

V-grooving, also known as V-cutting, is a process for cutting grooves in flat sheet metal and serves as an auxiliary step to shearing and bending. After V-grooving, the sheet has clear reference lines for shearing and bending; following the bend the fillet can be removed to achieve a true right-angle bend.

V-grooving is an auxiliary forming operation: at the intended bend line special equipment and tooling cut a V-shaped groove so the material can be bent more easily and the outer bend radius is minimized. The bent part is then formed on a press brake or manually. The V-groove’s depth, width, and angle are determined and controlled by the cutter geometry and the cutting/feed depth during the grooving operation.

Stationary workpiece for high-speed, precision V-grooving of decorative panels.

√ Capabilities: 0.4-5.0 mm

√ Speed: 0-120 m/min

√ Stationary sheet processing

90° rotating tool holder — one-clamp four-side grooving for superior diagonal accuracy.

√ Capabilities: 0.4-5.0 mm

√ Speed: 0-120 m/min

√ Transverse and longitudinal

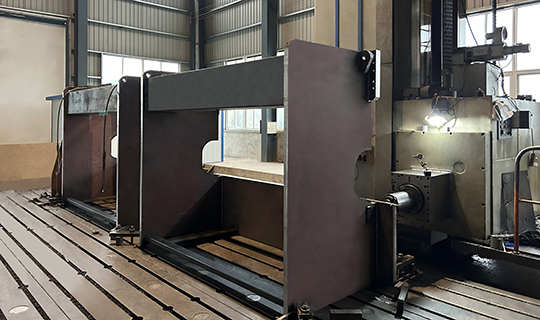

Workpiece feeds under cutter for high rigidity — ideal for irregular shapes and large panels.

√ Capabilities: 0.4-6.0 mm

√ Speed: 0-120 m/min

√ Movable sheet processing

Dual tool holders groove on both strokes, using return travel to boost thick-plate throughput.

√ Capabilities: 0.4-6.0 mm

√ Speed: 0-120 m/min

√ Two tool holders with two directions

Single-clamp laser cutting+ v-grooving — no re-indexing, higher precision.

√ Capabilities: 0.4-6.0 mm

√ Speed: 0-120 m/min

√ Laser Power: 1.5/3.0 kW

Video demonstration

On site case

Application field

Stainless steel decoration

Architectural decoration

Automobile manufacturing

Metal furniture

Appliance sheet metal

Kitchen & Cabinet manufacturing

Hotel kitchen equipment

Kitchenware

Elevator

Bathroom

Anti-skid plates

Display fixtures

Display props

Advertising signs

Hardware products

Stainless steel processing

Industrial equipment enclosures

Metal doors & Security systems

Why choose Jianmeng

We sell directly to you, eliminating intermediary costs and providing competitive prices

We provide lifelong service to ensure worry free after-sales service for you

We have been deeply involved in the mechanical manufacturing industry for many years and have very rich experience

Our equipment framework has undergone heat treatment to ensure accuracy and prevent deformation

Powerful quality control processes ensure that every machine meets strict performance standards

We provide very comprehensive paper and even video materials to give you a comprehensive understanding of Jianmeng equipment

More Info? Get In Touch