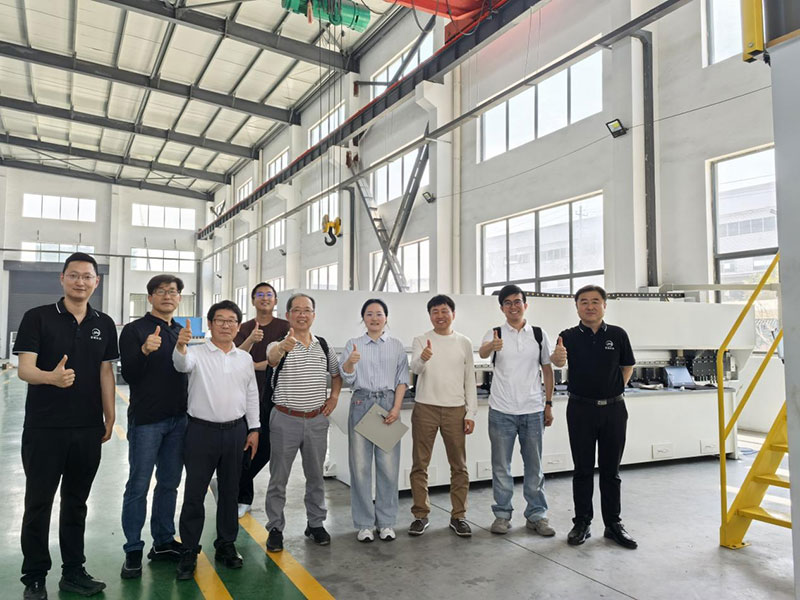

Expanding New Markets · Strengthening Long-Term Partnerships— JM’s Indonesia Customer Visits And Industry Exhibition Tour Successfully Concluded

In early December, the JIANMENG team embarked on a one-week market visit to Indonesia. The trip included visits to key existing customers, meetings with potential new clients, and attendance at a major local industry exhibition. The purpose of this journey was to further strengthen customer relationships, gain deeper insights into market trends, and continue expanding JM’s presence in the Indonesian market.

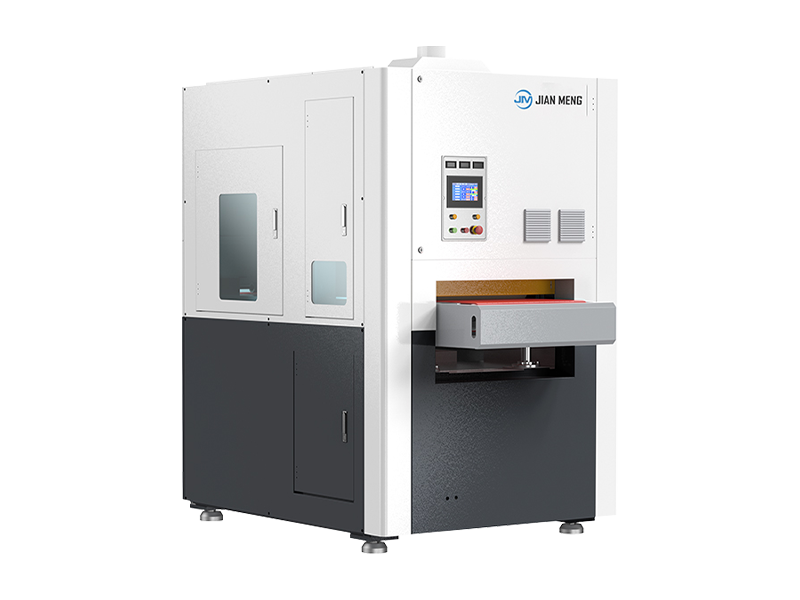

During the customer visits, the team went deep into production workshops to observe machine performance and real-world applications. In-depth discussions were held with customers regarding processing techniques, efficiency improvements, and future expansion plans. Based on each customer’s specific requirements, the team provided tailored recommendations and optimization suggestions, helping customers improve productivity and earning strong recognition from them.

In addition to customer visits, the team also attended an important industry exhibition in Indonesia. By closely observing the latest technologies, equipment developments, and application trends from both local and international players, JIANMENG gained valuable insights into the Indonesian and regional markets. The exhibition also provided opportunities for face-to-face communication with industry profe...

2025-12-22

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian