Video demonstration

- HOME

- ABOUT

-

PRODUCTS

- Forming machine

- Deburring machine

- XDP-RP Series deburring machine

- XDP-RR Series deburring and brushing machine

- XDP-MRP Series carbon steel deburring machine

- XDP-RPR Series deburring and surface finishing machine

- XDP-MRPR Series carbon steel deburring and surface finishing machine

- XDP-RPRT Series surface finishing and polishing machine

- XDP-MRPRT Series carbon steel surface finishing and polishing machine

- XDP-RRT Series deburring and polishing machine

- XDP-WRR Series flat surface wet brushing machine

- XDP-WDC Series wet dust collector

- XDP-SD Manual deburring machine

- Press brake

- Shearing machine

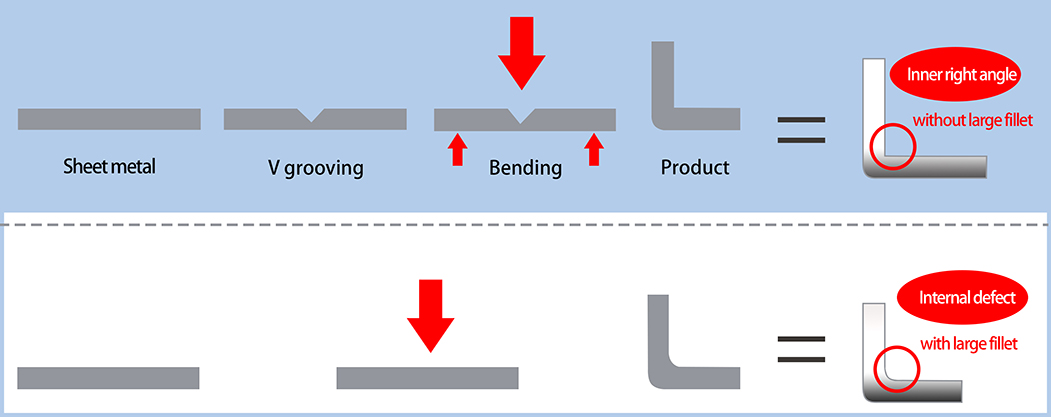

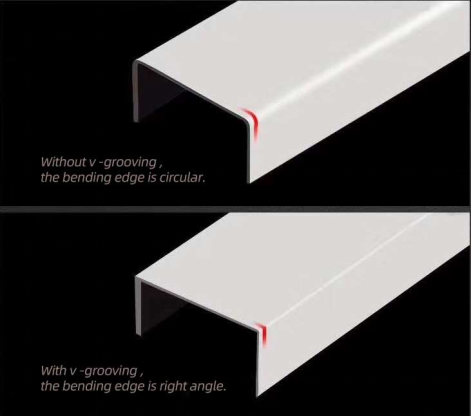

- V grooving machine

- Notching machine

- NEWS

- CONTACT

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian