A Comprehensive Guide To Restoring Classic Old Cars: From Disassembly To Revitalization And Inheriting Automotive Culture

Release time:2025-10-26

Visits:187

Restoring old cars is not only about restoring their mechanical performance but also a tribute to the history of the automotive industry. This complex project that integrates mechanical engineering, materials science, and artistic aesthetics requires systematic operations to achieve a dual improvement in the vehicle's performance and aesthetic value.

I. Core Restoration Process

1. Comprehensive Vehicle Condition Diagnosis

Use ultrasonic flaw detectors and three - dimensional scanning technology to accurately locate areas of metal fatigue and structural damage on the vehicle body. Focus on inspecting key parts such as the longitudinal beams and A/B pillars. Simultaneously record 28 core data items, including the engine cylinder pressure and the meshing degree of the transmission gears, to provide a scientific basis for the restoration plan.

2. Professional - Level Disassembly Operations

(1) Establish a parts classification and coding system to digitally archive over 2000 parts of the whole vehicle.

(2) Soak rusted threads with lithium - based lubricant to avoid secondary damage caused by violent disassembly.

(3) For all - aluminum bodies, use liquid nitrogen freezing separation technology to ensure the integrity of the joint surfaces.

3. Regeneration Technology for Key Components

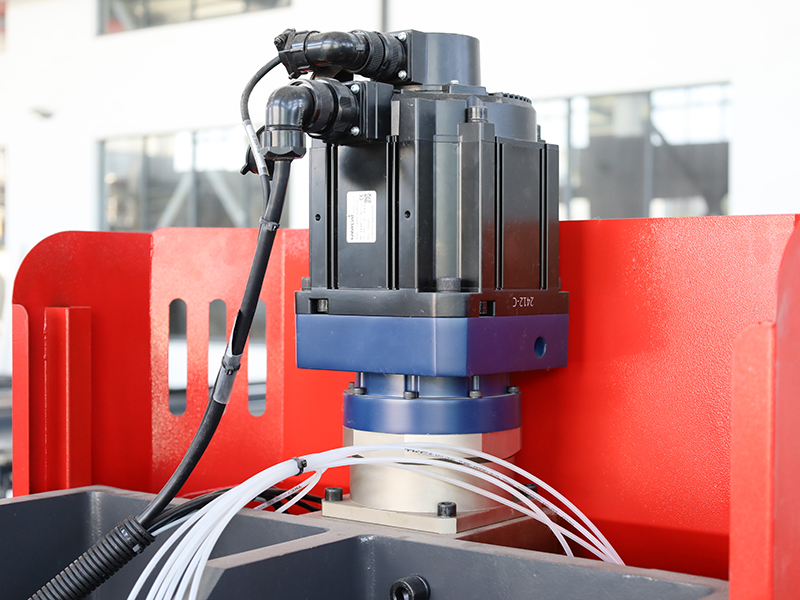

For the engine, use nano - metal ceramic coatings to repair scratches on the cylinder block, and cooperate with laser cladding technology to repair crankshaft wear. For the electrical system, use modular diagnostic instruments to restore ECU data, and implement double - layer silicone insulation treatment on aging wiring harnesses. For the chassis system, restore the suspension geometric parameters through the cold - rolling correction process, with the error value controlled within ±0.05mm.

4. Triple Process for Body Restoration

(1) Structural Restoration: Use MIG brazing to repair rust - perforated holes, with the weld strength reaching 98% of the original factory level.

(2) Surface Treatment: Polish through six processes to a cleanliness level of Sa2.5, with a cathode electrophoretic primer film thickness of 30μm.

(3) Color Restoration: Use a spectral analyzer to extract data from residual paint chips, and use a numerically controlled paint - mixing system to accurately reproduce the original factory color code.

II. Professional Restoration Principles

1. Restoration of Original Factory Processes

Strictly abide by the assembly tolerance standards set during the vehicle's design, and focus on referring to the torque parameters in the original factory maintenance manual. For discontinued mechanical parts, use reverse engineering combined with 3D metal printing for manufacturing.

2. Application of Environmental - Friendly Technologies

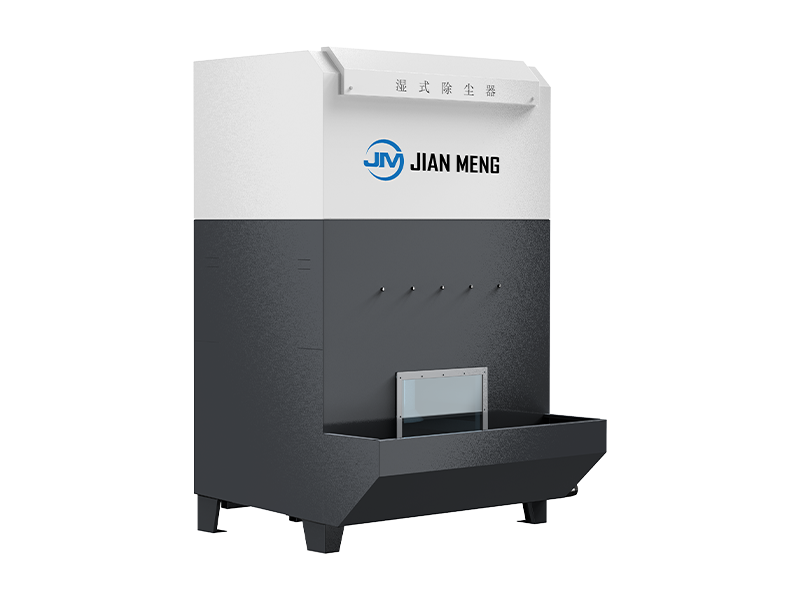

Replace traditional paints with water - based high - solid coatings, reducing VOC emissions by 75%. Establish a closed - loop cleaning system to achieve zero waste liquid discharge, with a metal scrap recovery rate of up to 92%.

3. Protection of Cultural Value

Retain design elements with era - specific features, such as chrome - plated dashboard decorations and leather stitching styles. Establish a restoration log archive to completely record the traceability information of parts and process parameters.

III. Long - Term Maintenance System

Establish a special inspection system for the 500 - kilometer running - in period, focusing on monitoring the matching status of the powertrain. It is recommended to perform maintenance on the paint surface's crystalline coating annually and replace the vehicle's sealing rubber strips every three years. Implement micro - oxygen anti - corrosion treatment on metal parts to effectively delay the oxidation process by 8 - 10 years.

The restoration of old cars is transitioning from simple mechanical restoration to cultural inheritance. Through the combination of modern technology and traditional craftsmanship, not only can the mechanical soul of classic models be awakened, but also a living sample can be left for the history of the automotive industry. A professional and standardized restoration process can not only ensure the vehicle's safety performance but also retain its historical value to the greatest extent, enabling classic designs to regain vitality in the new era.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian