Deburring Machines: A Comprehensive Analysis Of Working Principles, Type Selection, And Application Fields

Release time:2026-01-04

Visits:102

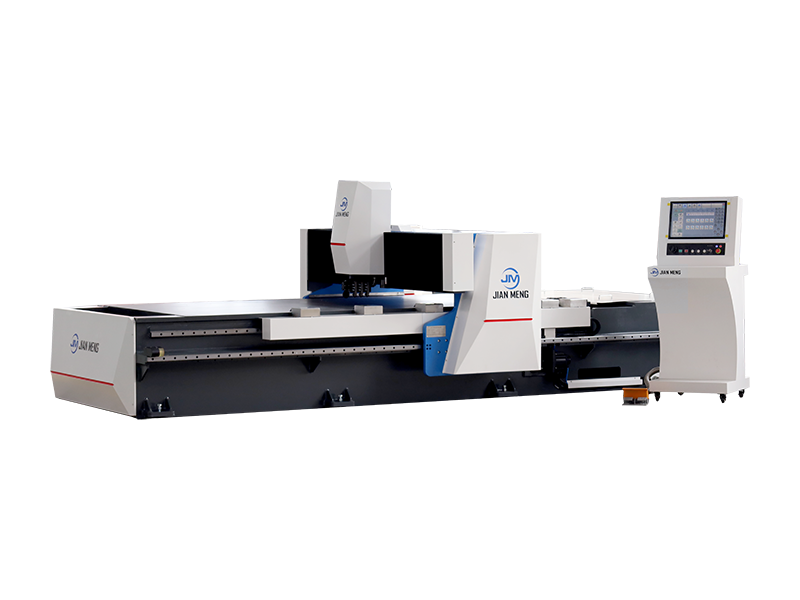

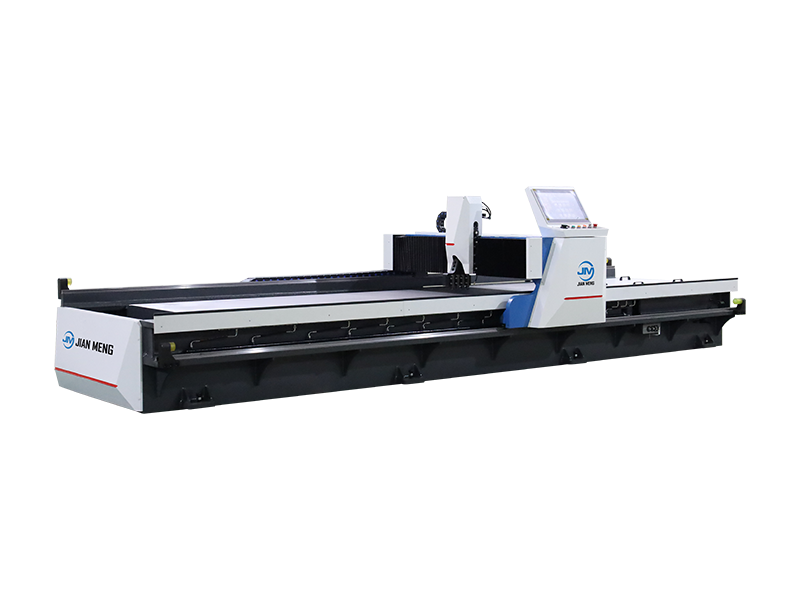

A deburring machine is an industrial device specifically designed to remove burrs from the surfaces of workpieces made of materials such as metal and plastic. Burrs are typically generated during cutting, milling, stamping, or casting processes, which can directly affect the dimensional accuracy, assembly performance, and service life of parts. To meet the characteristics of different workpieces and production requirements, deburring machines employ various technologies to achieve efficient processing and are widely used in industries such as automobile manufacturing, aerospace, and precision electronics.

1. Mechanical Deburring Technology

- Barrel Deburring Machine: Workpieces and abrasives are placed in a rotating barrel, and burrs are removed through friction. It is suitable for batch processing of small regular parts, but the processing accuracy is relatively low.

- Vibratory Deburring Machine: High - frequency vibration is used to make the workpieces and abrasives rub against each other rapidly. It can process parts with complex shapes, but vibration parameters need to be adjusted according to the material to avoid surface damage.

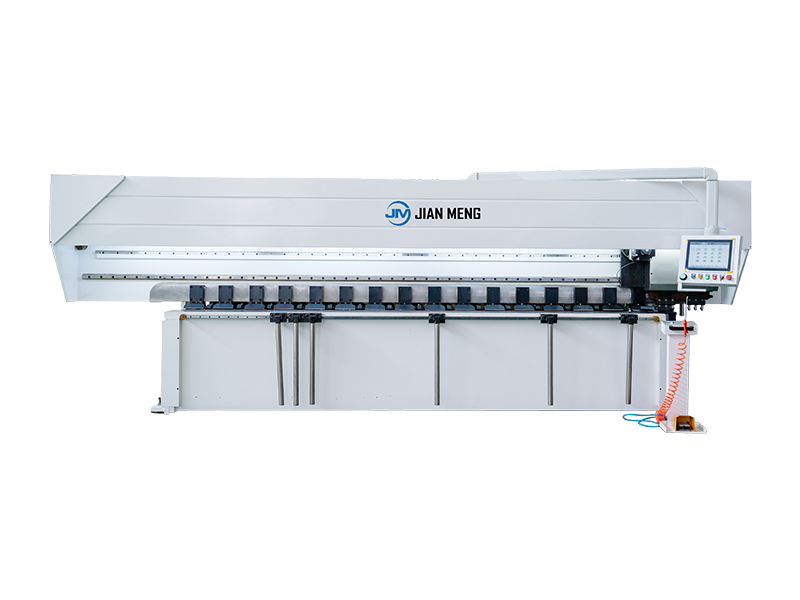

- Belt Deburring Machine: It uses a high - speed abrasive belt with a rotational speed of 10 - 35 m/min. The pressure of the abrasive belt is controlled by constant - pressure compressed air to achieve precise grinding. The abrasive belt can be easily replaced. It is especially suitable for efficient deburring of stamped parts and thin - walled parts, and the surface treatment quality is better than that of traditional roller - type grinding wheels [1].

2. Special Process Deburring Technology

- Electrolytic Deburring Machine: It uses the action of electrolyte and electric current to dissolve burrs without contacting the workpiece surface. It is suitable for deburring high - hardness metals or precision inner holes.

- Laser Deburring Machine: A high - energy laser beam is used to instantly vaporize burrs, with an accuracy of up to the micron level. It is commonly used in ultra - precision processing scenarios such as semiconductor components.

- Ultrasonic Deburring Machine: Burrs are removed by the impact of high - frequency vibration waves. It is especially suitable for cleaning and polishing small holes or electronic components.

II. Core Working Principles and Automation Processes

The working process of a deburring machine is usually divided into three stages: positioning, cutting, and cleaning.

1. Positioning and Speed Control: When a workpiece enters the detection area of the device (such as the position of a grating sensor), the transmission speed is automatically adjusted to the deburring mode. For example, after a slab is cut by continuous casting and conveyed to the deburring machine, the system precisely triggers the action of the tool through grating positioning to ensure accurate burr removal.

2. Dynamic Cutting Execution: Tools such as abrasive belts, cutters, or lasers come into high - speed contact with the burr area. Some devices use electromagnetic force to drive the grinding needle, and multi - angle grinding is achieved through adjustable head movement, and cleaning and polishing are completed simultaneously.

3. Self - cleaning and Resetting: After cutting, the device automatically executes the cleaning program (such as turning the plunger cross - beam 90° to remove residual debris) and resets to the initial state to ensure the stability of continuous production [4][5].

III. Key Factors in Selecting a Deburring Machine

1. Compatibility with Workpiece Characteristics: The hardness of the material (such as aluminum alloy and stainless steel) and the complexity of the shape (such as deep holes and curved surfaces) directly affect the selection of the device. For example, belt - type devices are more suitable for the thin - walled structure of stamped parts, while electrolytic technology is suitable for processing the inner holes of cemented carbide.

2. Balance between Precision and Efficiency: Laser technology can achieve an accuracy of 0.01 mm, but the cost is relatively high. Vibratory devices are suitable for mass production with medium precision.

3. Control of Production Costs: The purchase cost, energy consumption, and maintenance cost of the device need to be comprehensively considered. For example, ultrasonic devices have low power consumption but a short maintenance cycle, which are suitable for high - frequency, small - batch scenarios.

IV. Typical Industry Application Scenarios

1. Automobile Manufacturing: Key components such as engine blocks and transmission gears need high - precision deburring to ensure assembly sealing.

2. Electronics Industry: Burrs from drilling on PCB boards and sharp edges of connectors rely on laser or ultrasonic devices for micron - level processing.

3. Aerospace: Complex structural parts such as turbine blades and hydraulic pipelines use electrolytic or laser technology to avoid stress concentration.

V. Future Development Trends

With the intelligent upgrade, deburring machines are developing in the direction of integrating visual inspection and adaptive parameter adjustment. For example, the size of burrs is analyzed in real - time through AI algorithms, and the pressure of the abrasive belt or the energy of the laser is dynamically adjusted, which can further improve the processing consistency and reduce manual intervention.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian