Analysis Of The Core Functions Of Metal Finishing Machines And Selection Guide: Key Equipment For Improving Processing Efficiency

Release time:2026-01-07

Visits:99

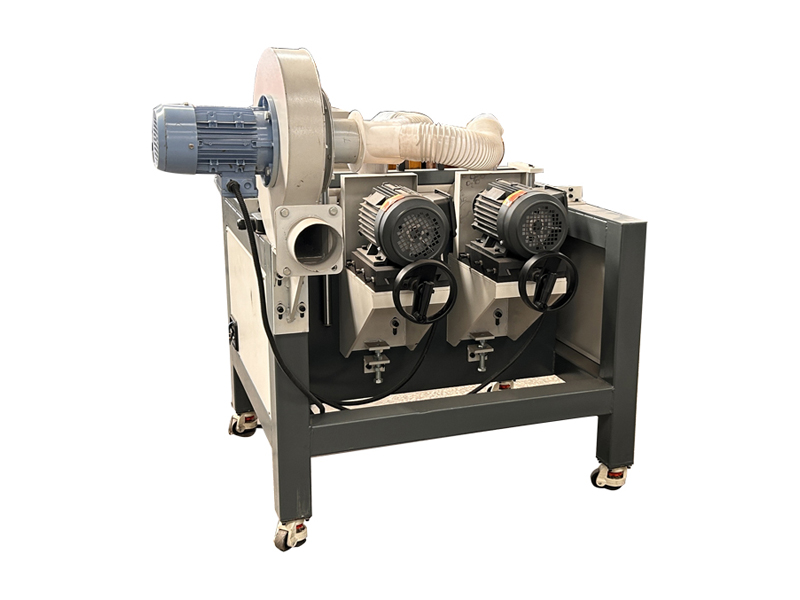

As an important piece of equipment in the field of metal processing, metal finishing machines are widely used in fields such as mechanical manufacturing, automotive parts repair, and aerospace precision processing. Their core functions are to repair, reshape, and perform fine - processing on metal workpieces, thereby improving the appearance quality and dimensional accuracy of products. This article will conduct an in - depth analysis of the core functions, mainstream types, and selection techniques of such equipment to help enterprises optimize their production processes.

Deburring and rounding system

Five Core Functions of Metal Finishing Machines

1. Deburring: For the burrs on the surface of workpieces after casting, cutting, or stamping, high - speed rotating cutters are used to quickly clean them up, avoiding assembly errors or safety hazards caused by burrs in subsequent processes.

2. Precision Chamfering: Professional chamfering cutters are used to process the edges of workpieces into a 0.1 - 1.5mm bevel. This not only enhances the aesthetic appeal of the products but also reduces the risk of scratches to operators caused by sharp edges.

3. Surface Polishing: Finishing machines equipped with polishing wheels of different meshes can achieve multi - level effects from basic grinding to mirror - finish treatment. They are particularly suitable for fields with strict requirements for surface roughness, such as medical devices and precision molds.

4. Deformation Correction: Through the pressure adjustment system, the bending and warping of metal parts can be precisely reshaped to restore the original geometric shape of the workpieces, which is especially suitable for automobile sheet metal repair scenarios.

5. Fine - processing Optimization: High - end models integrated with a measurement feedback system can achieve a processing accuracy of ±0.01mm, significantly improving the dimensional consistency and assembly adaptability of workpieces.

Classification of Mainstream Models and Application Scenarios

According to the degree of automation, the current market is mainly divided into three categories:

- Manual Type: The processing path is controlled by the operator. It is suitable for small - batch customized production or use in repair workshops. The advantages are low equipment cost and adaptability to irregular - shaped workpieces, but it requires a high level of operator skills.

- Semi - automatic Type: The tool path is controlled by pre - set programs, and the operator is responsible for loading and unloading workpieces and parameter adjustment. This type balances efficiency and flexibility and is suitable for the batch processing needs of medium - sized enterprises.

- Fully Automatic Type: Equipped with a multi - axis linkage system and a visual positioning module, it can achieve continuous automated production. Most of these devices are equipped with intelligent detection functions, which can correct processing errors in real - time. They are particularly suitable for the large - scale manufacturing of automotive parts and 3C electronic products.

Key Points for Selecting Key Configurations

1. Spindle Performance: It is recommended to choose a variable - frequency motor with a speed range of 500 - 15000rpm, which can meet the needs of rough processing such as deburring and also take into account the high - speed polishing process.

2. Tool Compatibility: High - quality equipment should support a quick - change tool system and be compatible with various processing tools such as carbide milling cutters, diamond grinding wheels, and nylon brushes.

3. Fixture System: Hydraulic/pneumatic fixtures with a modular design can stably fix irregular - shaped workpieces. When combined with a zero - point positioning system, the clamping time can be reduced by more than 90%.

Equipment Purchase and Maintenance Strategies

When purchasing, the following points should be focused on: the hardness of the processing material (it is recommended to choose a dedicated model for materials such as stainless steel and aluminum alloy), the daily output (for batch production, models with automatic loading and unloading are preferred), and site limitations (compact designs are more suitable for small and medium - sized workshops). For daily maintenance, a three - level maintenance system should be established: operators should clean up metal chips daily and check the lubrication system; the technical team should detect the radial run - out error of the spindle monthly; and the positioning accuracy of the numerical control system should be calibrated annually.

As basic equipment in modern manufacturing, the reasonable selection and efficient application of metal finishing machines directly affect an enterprise's quality control ability and production cost. Enterprises should establish a scientific equipment evaluation system based on their own product characteristics, select suitable models according to the processing technology requirements, and at the same time establish standardized operating procedures to maximize the potential of the equipment.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian