Guide To The Working Principle, Type Selection, And Industry Applications Of Leveling Machines (Flattening Machines/Straightening Machines)

Release time:2026-01-18

Visits:105

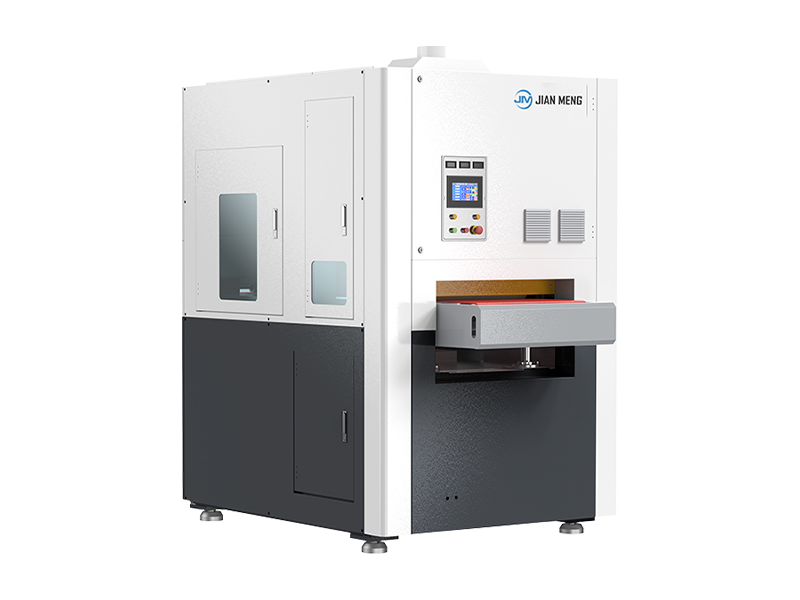

A leveling machine, also known as a flattening machine or straightening machine, is a key piece of equipment that corrects defects such as bending and warping of metal sheets through mechanical force. It can eliminate the internal stress generated during the rolling, cutting, or transportation of materials, providing metal parts with high flatness and stable surface quality for downstream processing. It is widely used in fields such as machinery manufacturing, the automotive industry, and shipbuilding.

I. Core Functions and Technical Principles

The core function of a leveling machine relies on the principle of multi - roll alternating bending correction. Taking the roller - type leveling machine as an example, the equipment consists of upper and lower rows of driving rollers. The upper row of rollers is usually fixed on an adjustable movable cross - beam. By adjusting the distance and angle between the rollers, the metal sheet undergoes multiple elastic deformations when passing through the roller train. This repeated forward and reverse bending can gradually eliminate the internal stress of the material, ultimately achieving a uniform and flat effect. For example, for thicker sheets, the hydraulic pressure leveling machine can complete efficient straightening in one go through multiple sets of high - precision rollers combined with a fine - tuning system.

II. Three Major Mainstream Types and Applicable Scenarios

1. Roller - type Leveling Machine

- Multi - roller type: Suitable for thin sheets (such as stainless steel and aluminum sheets) or precision electronic components. High - precision leveling is achieved through more than 5 sets of working rollers, and the error can be controlled within the millimeter range.

- Two - roller/Three - roller type: It has a simple structure and is suitable for the initial straightening of heavy - duty steel or construction profiles.

2. Tension Leveling Machine

By applying a controllable tensile force to the sheet, it solves the problem of extensional deformation of ultra - thin metal strips (such as copper foil) or high - strength alloys, and is commonly used in high - end manufacturing.

3. Pressure Leveling Machine

Driven by a hydraulic system, it can process steel plates with a thickness of more than 50mm or special cross - section profiles, such as the local correction of shipbuilding decks or bridge structural parts.

III. Industry Applications and Automation Integration

The application of leveling machines has penetrated into multiple key links of modern industry:

- Automobile manufacturing: It corrects the body sheets to ensure the flatness of stamped parts and improve the welding accuracy.

- Electronics industry: It processes the base materials of circuit boards to avoid component assembly failures caused by warping.

- Construction and shipbuilding: After correcting large - scale steel structural parts, the assembly efficiency and safety can be improved.

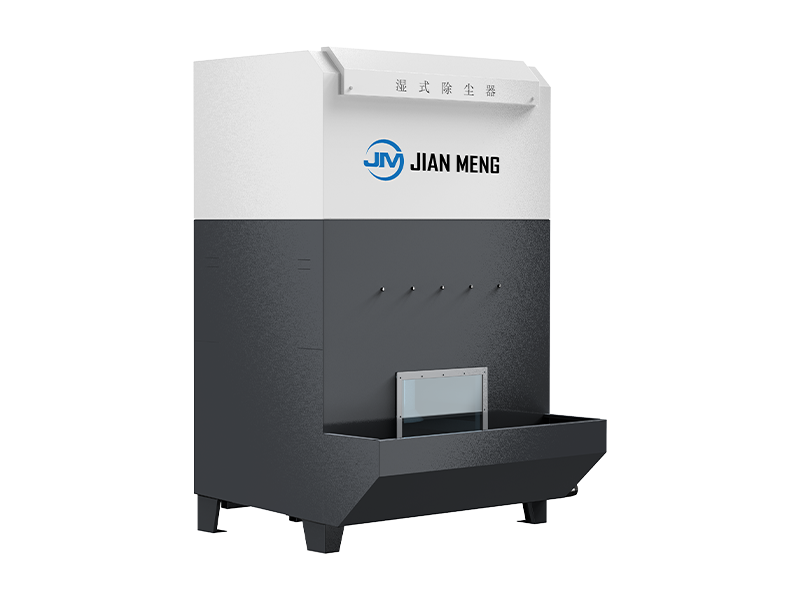

In an automated production line, the leveling machine is often linked with equipment such as punch presses and laser cutting machines. For example, the stamped parts directly enter the leveling unit through the conveyor belt, and the variable - frequency speed - regulation system is used to match the production line rhythm to achieve continuous production without pauses. Some high - end models also support loading and unloading by manipulators, greatly reducing the need for manual intervention.

IV. Selection and Usage Suggestions

When selecting a leveling machine, the following factors need to be comprehensively considered:

1. Material characteristics: Select the roller diameter and pressure parameters according to the type of metal (cold - rolled sheet, galvanized sheet, etc.) and the thickness range (0.1 - 100mm).

2. Accuracy requirements: Precision electronic components require the selection of models that support fine - tuning at the 0.01mm level, while construction steel usually only needs to meet a tolerance of 1 - 2mm.

3. Maintenance cost: Multi - roller equipment needs regular lubrication and maintenance, and the state of the seals in the hydraulic system should be monitored to avoid leakage risks.

4. Safety design: It is advisable to choose models equipped with protective covers, emergency stop buttons, and overload protection functions to ensure the safety of operators.

In addition, users can conduct a trial run before purchasing to verify the performance of the equipment through the actual leveling effect of the sheets. Some suppliers also provide subcontracting processing services to solve the temporary leveling needs of small and medium - sized enterprises.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian