A Comprehensive Analysis Of Deburring Methods For Machined Parts: Core Technologies For Improving Precision And Efficiency

Release time:2026-01-28

Visits:100

In machining, burrs generated on the surface of parts directly affect their dimensional accuracy, assembly performance, and service life. Research shows that the shedding of burrs may increase the failure rate of mechanical systems by 70%, and even cause potential hazards such as the jamming of hydraulic components or short - circuits in electrical circuits. Therefore, the deburring process has become a key link in ensuring the quality of parts. This article systematically sorts out eight mainstream deburring technologies and their applicable scenarios to help enterprises optimize the production process.

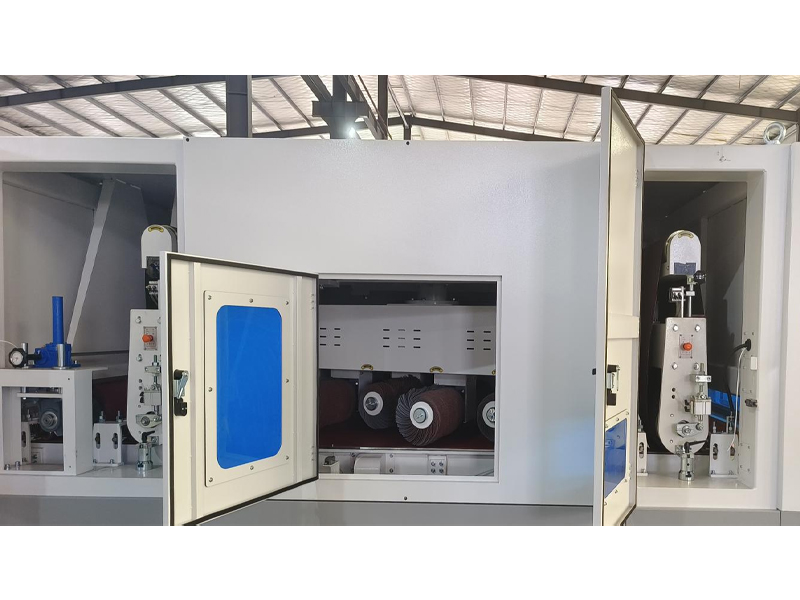

Metal Deburring Machine

I. Classification and Application of Deburring Technologies

1. Manual Deburring

Using basic tools such as files and sandpapers, it offers high flexibility and is suitable for small - batch production or parts with complex shapes. However, it incurs high labor costs and is difficult to control the consistency.

2. Mechanical Automation Deburring

Batch processing is achieved through dedicated equipment (such as vibration grinders and polishing machines), with the efficiency increased by 2 - 3 times. It is suitable for large - scale production scenarios, but requires a large initial equipment investment.

3. Chemical Corrosion Method

This method uses acidic or alkaline solutions to selectively dissolve burrs and can process micro - inner cavity structures. However, strict control of waste liquid discharge is required to avoid environmental pollution.

4. Electrolytic Deburring

Burrs are precisely removed through electrolytic reactions, which is especially suitable for precision parts made of cemented carbide. It has a relatively high technical threshold and requires professional equipment support.

5. Thermal Energy Treatment Method

Instantaneous high temperature is used to melt and remove metal burrs, which is suitable for high - strength alloy parts. However, the temperature needs to be precisely controlled to avoid deformation of the base material.

6. Ultrasonic - Assisted Process

Micro - burrs are peeled off through high - frequency vibration. It is widely used in the medical device and semiconductor fields and can process gap structures that are difficult to reach with traditional tools.

7. Laser Precision Machining

High - energy laser beams are used to instantaneously vaporize burrs, with the precision reaching the micron level. It has gradually replaced some imported equipment and become an important solution in the field of precision manufacturing.

8. Magnetic Abrasive Finishing Technology

By utilizing the dynamic movement of magnetic abrasives in a magnetic field, complex curved surfaces and micro - holes can be processed simultaneously, and the processing efficiency is more than 40% higher than traditional methods.

II. Core Elements of Technology Selection

- Material Compatibility: For soft metals such as aluminum alloy, mechanical or magnetic abrasive finishing is preferred; for hard and brittle materials such as titanium alloy and ceramics, laser or electrolytic processing is more suitable.

- Process Economy: For small - batch production, it is recommended to use a combination of manual and semi - automatic equipment; when the monthly output exceeds 10,000 pieces, the unit cost of fully automatic equipment can be reduced by 60%.

- Precision Requirements: In the aerospace field, when the precision requirement is at the 0.01mm level, laser and electrolytic methods have more advantages; for conventional industrial components, economical solutions such as vibration grinding can be adopted.

- Environmental Compliance: The chemical method requires a waste liquid recovery system; the thermal energy method needs to be equipped with an exhaust gas treatment device to meet environmental regulations.

III. Industry Development Trends

In the field of high - end equipment, domestic enterprises are accelerating the breakthrough of technical barriers. For example, the new six - axis CNC slow - wire cutting machine has achieved autonomy, with the processing efficiency three times higher than traditional equipment and the precision reaching the micron level. In the field of laser processing, domestic equipment is gradually replacing imported products, helping manufacturing enterprises save up to 80% of tool procurement costs. With the intelligent upgrade, automated deburring production lines integrated with visual inspection will become the mainstream solution, promoting the continuous development of the manufacturing industry towards high - quality and high - efficiency.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian