Laser Cutting Technology: An Analysis Of Core Principles, Advantages, And Application Areas

Release time:2026-02-01

Visits:107

As a core process in modern manufacturing, laser cutting technology utilizes a high - energy - density laser beam to achieve efficient material processing. Since the birth of the laser in 1960, this technology has continuously evolved and become the preferred solution for processing both metallic and non - metallic materials. The following comprehensively analyzes laser cutting technology from aspects such as technical principles, core advantages, applicable materials, application scenarios, and future trends.

Core Principle: The Synergistic Effect of Thermal Effect and Gas Flow

In laser cutting, a high - power laser beam is generated by a laser generator and then focused by a focusing lens into an extremely small spot (usually with a diameter of 0.1 - 0.3 mm), generating an energy density as high as 10⁶ - 10⁸ W/cm². When the beam acts on the material surface, the instantaneous heating causes the material to rapidly melt, vaporize, or burn. Meanwhile, high - pressure gas (such as oxygen or nitrogen) coaxial with the beam blows away the molten material, forming a smooth cutting seam. This process can be divided into four modes according to the material properties:

1. Vaporization Cutting: Used for non - metallic materials such as wood and plastic.

2. Melting Cutting: Suitable for metals such as stainless steel and aluminum alloy.

3. Oxidation Cutting: Improves the cutting efficiency of carbon steel through oxygen - assisted combustion.

4. Controlled Fracture: Used for the precise segmentation of brittle materials.

Technical Advantages: Revolutionizing Traditional Processing Methods

1. High Precision and High Speed

The positioning accuracy can reach 0.02 mm, and the cutting seam width is only 0.1 - 0.3 mm, making it suitable for micron - level precision parts. The cutting speed can reach 10 m/min, 5 - 10 times faster than traditional mechanical processing.

2. High - Quality Cut and Low Heat Affect

The cut has no burrs, and the surface roughness Ra ≤ 12.5 μm, reducing the need for secondary processing. The width of the heat - affected zone is less than 0.1 mm, effectively avoiding material deformation.

3. Material Adaptability and Flexibility

It can process more than 300 types of materials, including carbon steel, titanium alloy, ceramics, and composite materials, and supports the cutting of complex graphics without the need for custom - made molds.

4. Automation and Energy - Saving and Environmental Protection

The CNC numerical control system enables full - process automation, increasing the material utilization rate by 15% - 20% and reducing energy consumption by 40% compared with plasma cutting.

Applicable Materials and Industry Applications

Material Classification:

- Metallic Materials: Carbon steel (with a thickness of up to 30 mm), stainless steel, titanium alloy (aerospace - grade), copper foil (for the electronics industry).

- Non - metallic Materials: Acrylic (for advertising signs), carbon fiber (for automotive parts), PCB boards (for electronic components).

Core Application Areas:

1. Automobile Manufacturing: Body sheet metal parts, airbag sensors.

2. Aerospace: Engine blades, titanium alloy cabin structures.

3. Electronics and Electrical Appliances: Mobile phone middle frames, flexible printed circuit boards.

4. Medical Equipment: Precision processing of surgical instruments and orthopedic implants.

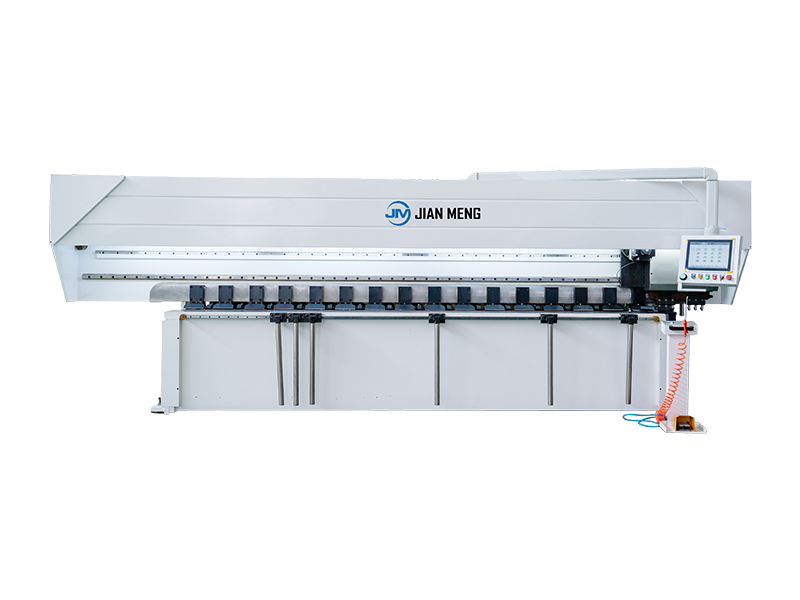

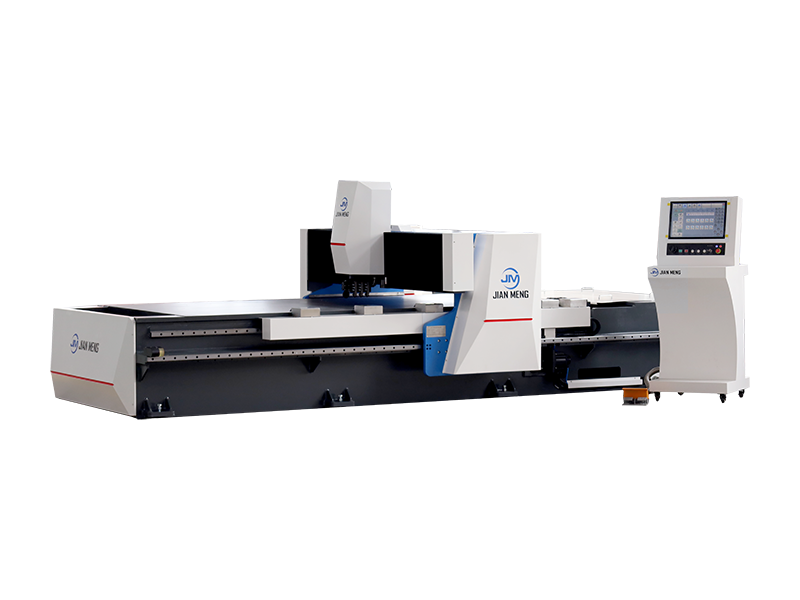

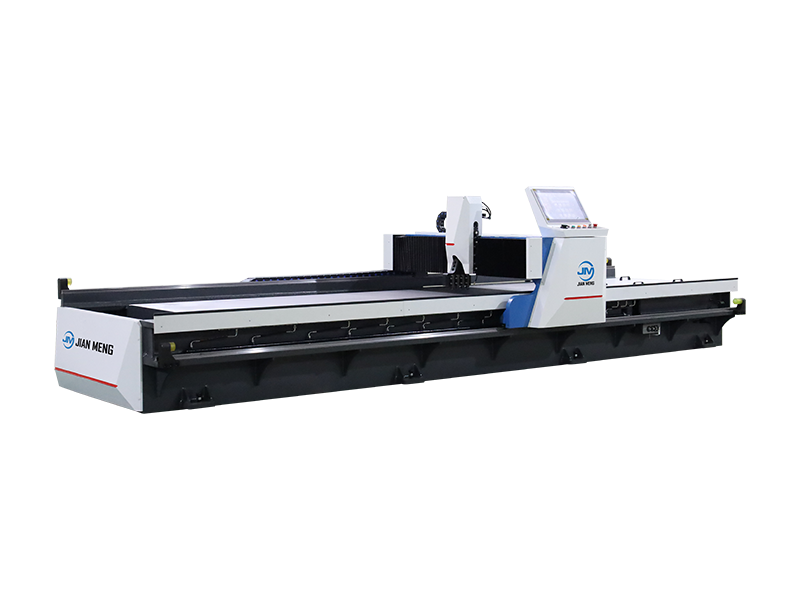

Equipment Types and Technological Iteration

1. CO₂ Laser Cutting Machines: With a wavelength of 10.6 μm, suitable for cutting non - metallic and thin metallic materials.

2. Fiber Lasers: With a photoelectric conversion efficiency of over 35%, the first choice for metal processing.

3. Ultraviolet Laser Equipment: With a wavelength of 355 nm, used for semiconductor wafer cutting.

Future Trends: Intelligent and Green Manufacturing

1. Power Upgrade: Ultra - high - power equipment above 30 kW can break through the cutting of 100 - mm - thick steel plates.

2. AI Integration: Machine learning algorithms optimize the cutting path, reducing energy consumption by 15%.

3. Multi - process Integration: Integrated cutting - welding - marking equipment improves the efficiency of production lines.

4. Environmental Protection Upgrade: The smoke purification system can filter 99% of particulate matter.

As a fundamental technology in the era of Industry 4.0, laser cutting will continue to drive innovation and breakthroughs in fields such as precision manufacturing and new - energy equipment. Enterprises adopting this technology can shorten the product development cycle by 50% and reduce the comprehensive cost by 30%, making it a strategic choice to enhance competitiveness.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian