A Comprehensive Analysis Of Cutting Machine Types: Application Scenarios And Purchase Guide

Release time:2026-03-15

Visits:100

As an indispensable processing equipment in modern industry, cutting machines can efficiently process various materials such as metals, wood, stone, and plastics. With technological advancements, their types and functions have been continuously enriched to meet the specific needs of different industries. This article provides a comprehensive analysis from the perspectives of types, applications, purchases, and safety to help users quickly grasp the core information.

1. Flame Cutting Machine

It heats the metal to its ignition point through an oxygen - fuel flame and blows away the molten metal with a high - speed oxygen stream to complete the cutting. It is suitable for relatively thick carbon steel plates. The advantages are low cost and the ability to cut large - sized workpieces, but there are problems such as rough cutting surfaces and obvious thermal deformation.

2. Plasma Cutting Machine

It melts the workpiece with a high - temperature plasma arc and can efficiently cut conductive metals such as stainless steel and aluminum alloy. It has a fast cutting speed and does not require pre - heating, but it has relatively high requirements for the operating environment. Fine plasma technology can achieve a precision close to that of laser cutting and supports underwater operations to reduce noise and dust pollution.

3. Laser Cutting Machine

It relies on a high - energy laser beam to melt materials, featuring high precision and smooth cutting edges. It is suitable for thin metal sheets and non - metals such as plastics and wood. It has a high degree of automation, but the equipment cost and energy consumption are relatively large, and strict requirements are placed on maintenance technology.

4. Water Jet Cutting Machine

It uses ultra - high - pressure water flow (which can be mixed with abrasives) for cold cutting, without a heat - affected zone. It is suitable for the fine processing of brittle materials such as glass and ceramics and composite materials. The disadvantages are a slow cutting speed and relatively high equipment cost.

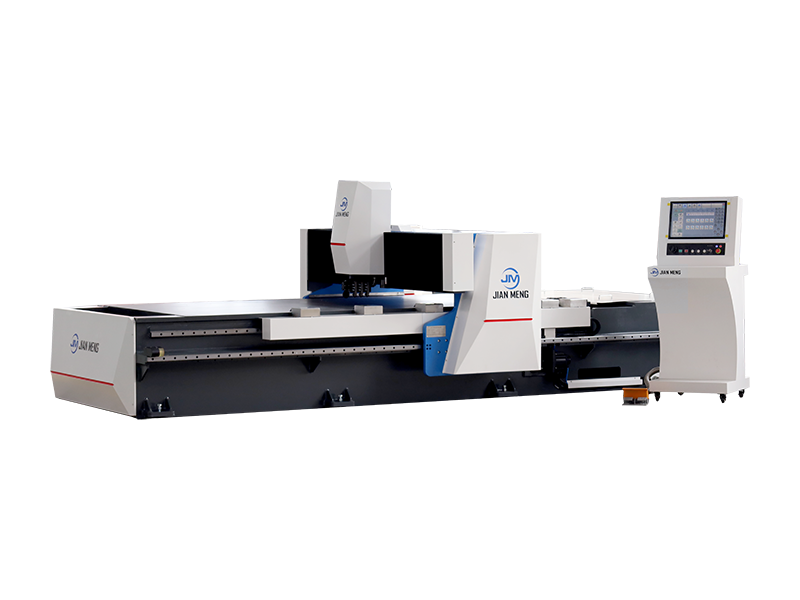

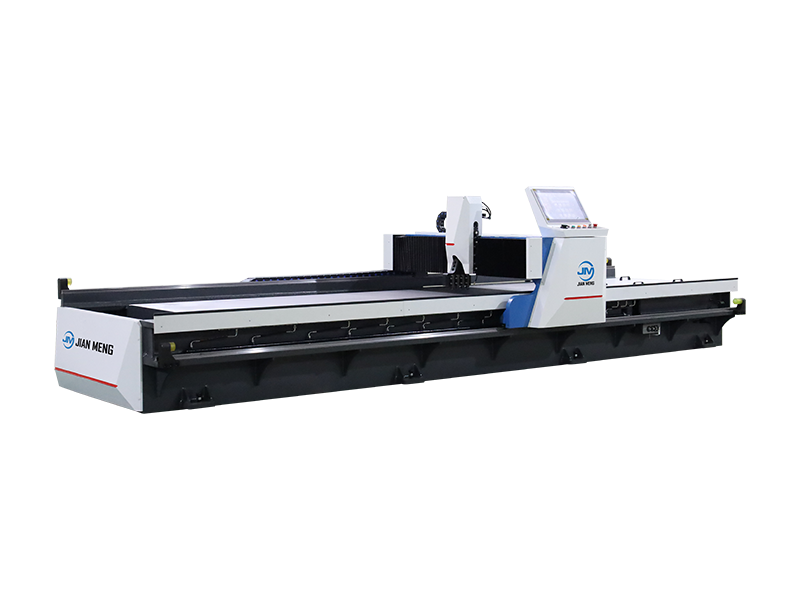

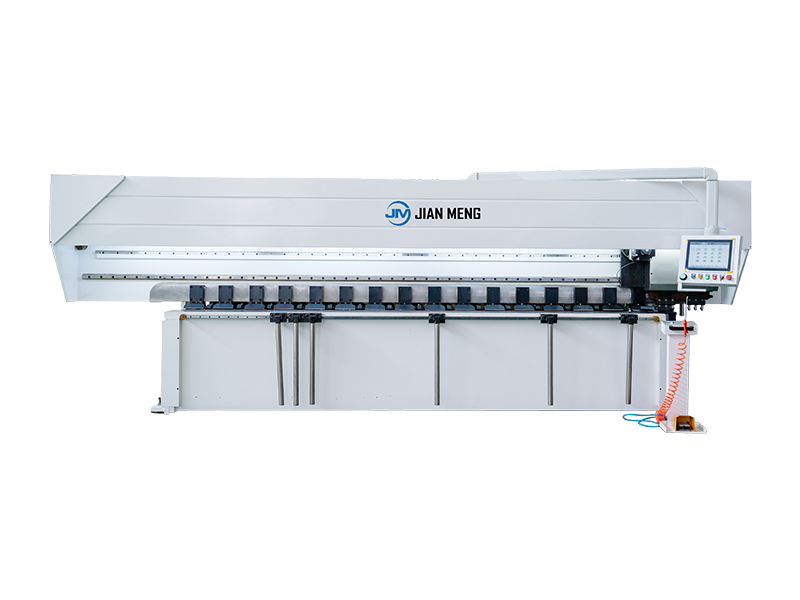

5. CNC Cutting Machine

It controls the cutting path through a CNC system and supports various energy combinations such as flame, plasma, and laser. The advantage lies in its high degree of automation, which can handle complex graphics and is widely used in mass production and customized processing scenarios.

Other types include Wire Cutting Machine (which corrodes metal through electric sparks, with extremely high precision and is suitable for mold manufacturing) and Straight Bar Cutting Machine (used for steel strip processing to improve efficiency and reduce thermal deformation).

II. Core Application Fields

- Manufacturing Industry: Cutting of metal sheets and pipes (such as automotive parts and machined parts).

- Construction Industry: Special - shaped cutting and slotting of stone and tiles.

- Wood Processing Industry: Cutting, carving of wooden boards, and furniture production.

- Advertising Industry: Processing of signs and decorative parts made of materials such as acrylic and PVC.

- Aerospace and Energy Industry: Customized cutting of high - precision metal components and composite materials.

III. Key Factors for Purchase

1. Material Compatibility

For carbon steel, flame cutting is a good choice; for stainless steel or aluminum alloy, plasma cutting is preferred; for non - metal materials, water jet or laser cutting is applicable.

2. Precision and Efficiency

In high - precision scenarios (such as electronic components), laser or CNC equipment is required, while for mass production, more emphasis is placed on cutting speed (such as plasma cutting).

3. Cost Control

Equipment purchase, consumables (such as laser gas and plasma electrodes), and maintenance costs need to be comprehensively considered. Small and medium - sized enterprises can choose a CNC flame/plasma integrated machine to reduce costs.

4. Operation Complexity

The CNC system requires professional training, while handheld devices are more flexible but have higher safety requirements.

IV. Safe Operation Specifications

- Training and Qualifications: Operators need to be familiar with equipment parameters and emergency procedures and work with proper certificates.

- Protective Measures: Wear goggles and fire - resistant gloves, and ensure good ventilation in the working area.

- Regular Maintenance: Check the air tightness of gas circuits, the wear of cutting tools, and the stability of the system.

- Emergency Response Plan: The equipment must be equipped with an emergency stop button, and fire - fighting equipment should be available at the work site.

V. Technological Trends and Future Outlook

CNC and intelligentization have become the mainstream trends. Some equipment has integrated AI algorithms to optimize the cutting path. At the same time, multi - energy composite cutting machines (such as laser + water jet) are gradually emerging, further expanding material adaptability. In the future, low energy consumption, high automation, and environmental protection will become the core directions of technological upgrading.

Whether in industrial production or customized processing, reasonably selecting the type of cutting machine and standardizing the operation process can significantly improve efficiency and product quality. It is recommended that users choose the most suitable equipment solution according to their actual needs, budget, and usage scenarios.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian