Comprehensive Analysis Of Automotive Parts Processing Technology: Core Technologies From Blanks To Finished Products

Release time:2026-04-08

Visits:103

Automotive parts processing is a complex process of transforming raw materials into precision parts, involving multiple fields such as materials science, mechanical engineering, and automation technology. As the cornerstone of the automotive industry, its technological level directly determines the performance and reliability of vehicles. The following is an analysis of the core technologies of automotive parts processing.

I. Key Links in the Processing Flow

1. Design and Material Selection

The development of parts begins with precise reverse engineering design, which needs to take into account both functional requirements and the overall vehicle layout. Commonly used materials include high - strength steel, aluminum alloy (reducing weight by 30%), engineering plastics (for interior parts), and composite materials (for chassis parts).

2. Blank Forming Technology

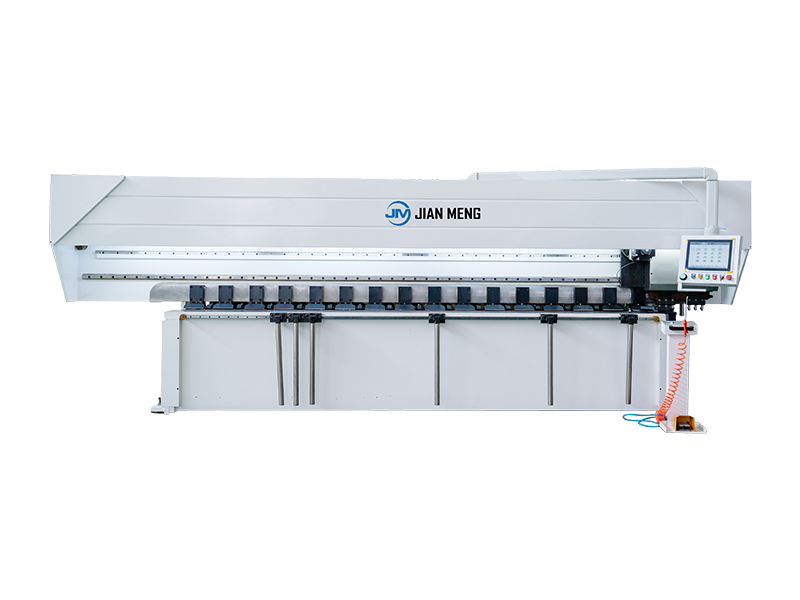

The casting process can mass - produce complex components such as engine blocks and transmission housings. Sand casting accounts for 90% of the total, while die - casting technology can manufacture precision aluminum parts with a wall thickness of only 2.5mm. The forging process uses a 5000 - ton hydraulic press to process high - strength components such as crankshafts and connecting rods, increasing the compactness of the microstructure by 40%.

II. Analysis of Core Processes

1. Precision Forming Technology

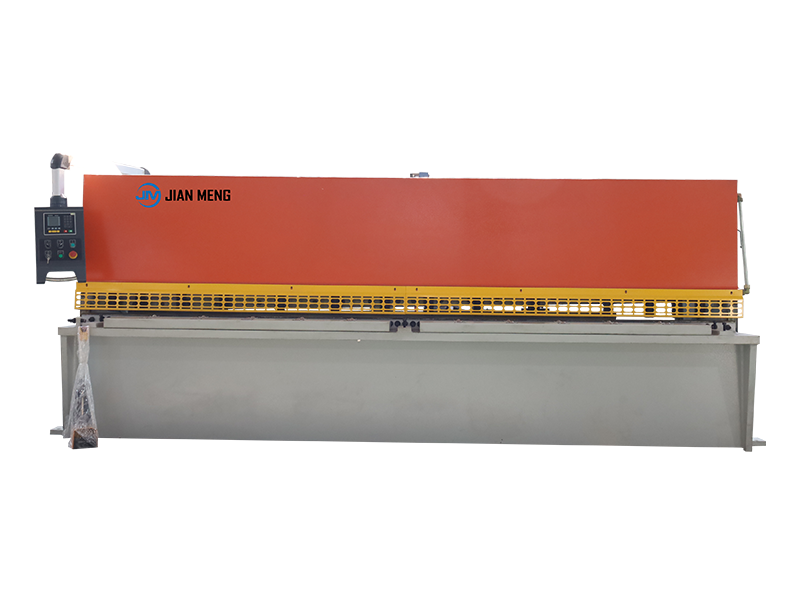

• Stamping process: Using multi - station progressive dies to achieve a production efficiency of 1 piece per second, it is used for manufacturing covers such as car doors and engine hoods, with an accuracy of up to ±0.03mm.

• Powder metallurgy: Used for manufacturing transmission gears, the material utilization rate reaches over 95%, and it saves 60% of energy compared with traditional cutting processing.

2. Joining and Surface Treatment

Laser welding reduces the number of body welding points by 30% while improving the structural strength. Friction welding used in the processing of aluminum alloy wheels can reduce the area of the heat - affected zone. Electrophoretic coating forms a 20μm protective layer. Combined with a nano - ceramic coating, it can extend the service life of brake discs by 3 times.

3. Special Processing

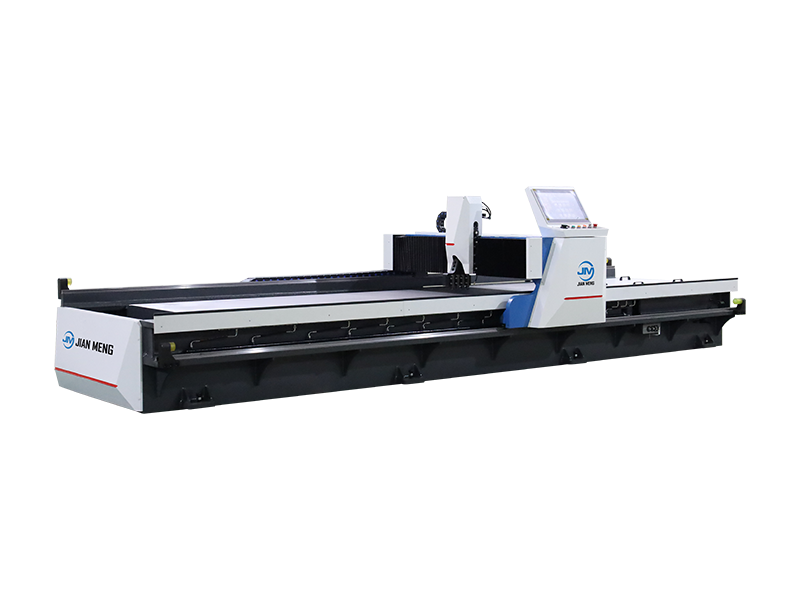

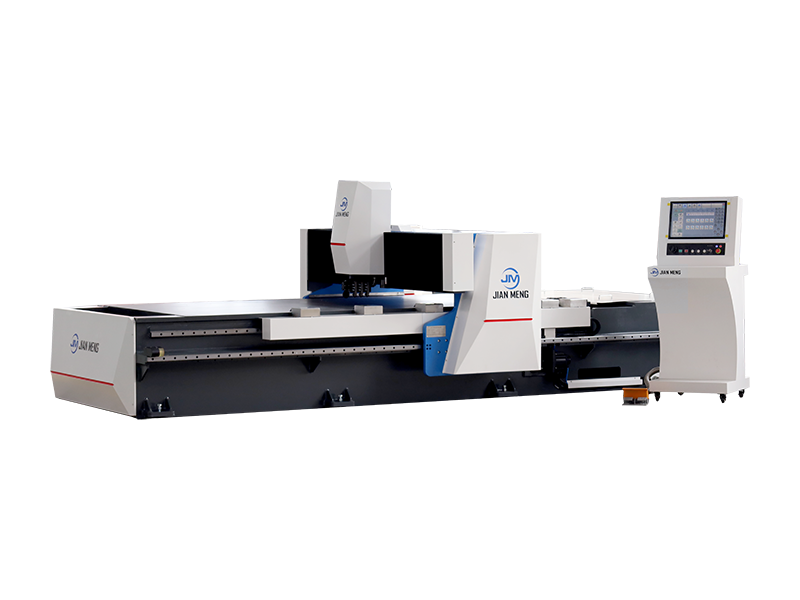

A five - axis machining center can complete the 0.01mm - level finishing of turbine blades. Laser cladding technology is used to repair engine valve seats, with a cost only 30% of that of replacing new parts.

III. Quality Monitoring System

The intelligent detection system runs through the entire production cycle:

• Online measuring instruments monitor the dimensional deviation of machining in real - time.

• Industrial CT can detect internal defects of 0.2mm level in castings.

• Fatigue test benches simulate 10 - year working conditions to verify the service life of suspension systems.

IV. Industry Development Trends

1. Digital Twin Technology: Building a virtual production line to optimize process parameters, the new product development cycle is shortened by 50%.

2. Application of Composite Materials: Carbon fiber drive shafts reduce weight by 60%, and ceramic brake pads can withstand temperatures up to 800°C.

3. Green Manufacturing: Aluminum scrap recycling and regeneration technology reduces energy consumption by 70%, and the replacement rate of water - based coatings has reached 85%.

Currently, the highly integrated intelligent manufacturing system controls the processing error within 1/5 of the hair diameter (±5μm), and the flexible production line can achieve the mixed - flow production of 200 kinds of parts. With the breakthrough of 3D printing technology, the cylinder head with a complex oil - passage structure has been integrally formed, and the traditional process flow is reduced by 60%. Automotive parts processing is continuously evolving towards micron - level accuracy, zero - defect delivery, and full - life - cycle traceability.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian