A Comprehensive Analysis Of The Core Technologies And Industry Applications Of Precision Machining Of Stainless Steel

Release time:2026-04-19

Visits:108

Precision machining of stainless steel is a key technology that involves in - depth processing of stainless - steel materials through a series of precise processes to improve their dimensional accuracy, surface finish, and comprehensive performance. Thanks to the excellent corrosion resistance, heat resistance, and mechanical strength of stainless - steel materials, the precision - machined parts are widely used in high - end fields such as medical devices, aerospace, and chemical equipment. The following are the core methods and implementation points of this process.

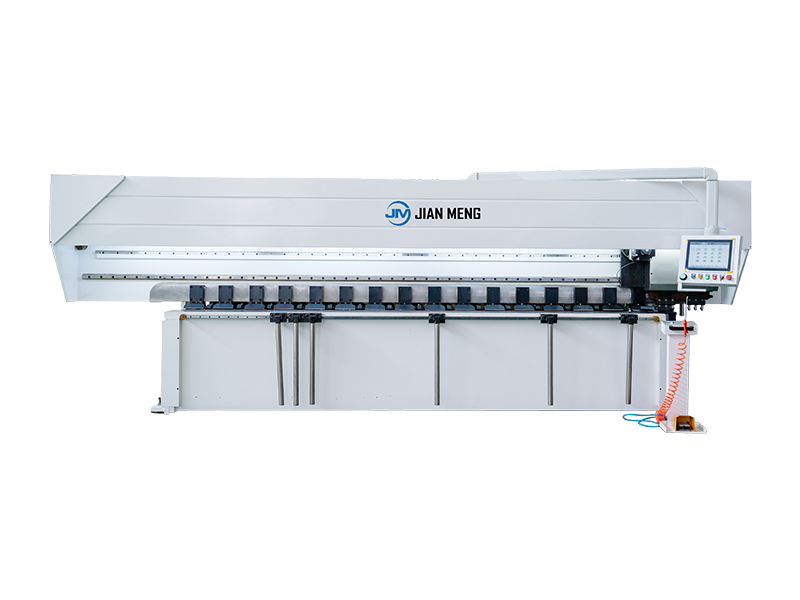

Metal edge rounding and deburring

Core Processes of Precision Machining of Stainless Steel

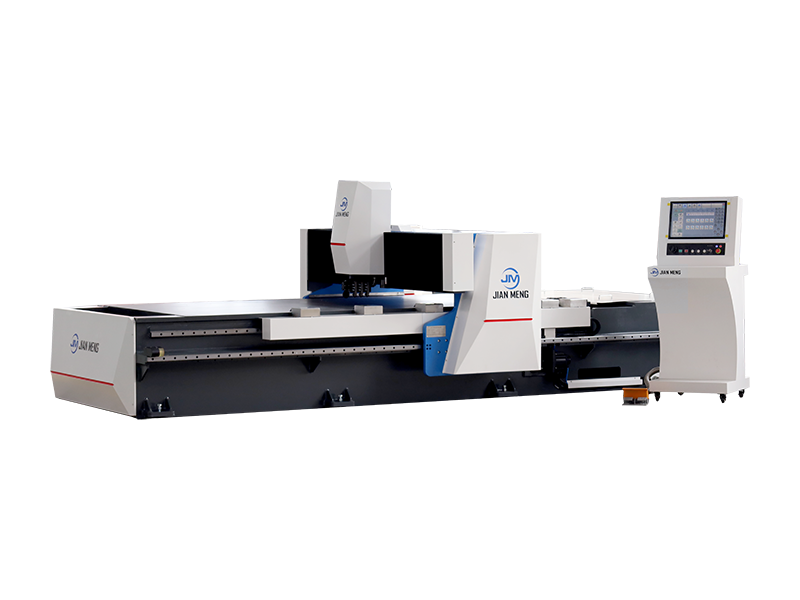

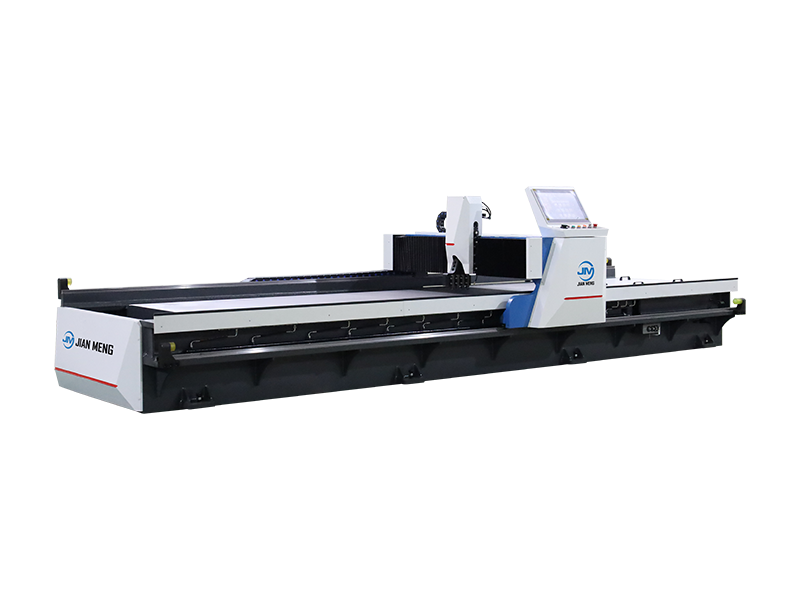

1. Turning and Milling Technologies

Turning uses CNC lathes to achieve high - precision forming of rotary parts (such as shafts and discs), while CNC milling is suitable for processing planar and three - dimensional parts with complex geometric features. Both types of technologies require special cutting tools to overcome the work - hardening characteristics of stainless steel and ensure processing efficiency and product quality.

2. Grinding and Electrical Discharge Machining

Surface grinders and cylindrical grinders can significantly improve the surface finish, with the precision reaching the micron level, which is especially suitable for precision instrument components. Electrical discharge machining (EDM) realizes the processing of complex cavities and micro - structures through discharge etching and is commonly used in mold manufacturing and the processing of super - hard materials.

3. Laser Cutting and Welding Processes

Laser cutting can efficiently complete the cutting of thin plates and special - shaped contours due to its non - contact processing advantage. In the welding process, TIG welding and MIG welding technologies can ensure the strength and corrosion resistance of the weld seams, meeting the high - requirement scenarios such as aerospace structural parts.

Five Key Elements for Process Optimization

1. Material Pretreatment and Tool Selection

Before processing, the hardness of different types of stainless steel (such as 304 and 316L) needs to be tested. Carbide tools or coated tools should be preferred to avoid tool wear caused by the material's viscosity.

2. Dynamic Temperature Control Strategy

Using water - based coolants and minimum quantity lubrication technology (MQL) can effectively reduce the temperature in the cutting area and reduce the risk of thermal deformation. During the processing, the temperature fluctuations need to be monitored in real - time, and the flow rate and pressure of the coolant should be adjusted.

3. Anti - deformation Clamping Design

Introducing hydraulic fixtures or vacuum adsorption devices and combining with the step - by - step processing method can reduce the processing stress of thin - walled parts. For components with a length - to - diameter ratio exceeding 5:1, auxiliary support mechanisms need to be configured.

4. Surface Treatment Enhancement

After precision machining, through electrolytic polishing or chemical passivation treatment, a dense oxide film can be formed on the surface, increasing the corrosion resistance by more than three times. In the medical device field, aseptic surface treatment is also required.

5. Trend of Intelligent Machining

The CNC system integrated with the Internet of Things can correct the processing parameters in real - time, reducing the reject rate to less than 0.2%. Some enterprises have introduced AI algorithms to optimize the tool path, shortening the processing cycle by more than 15%.

Analysis of Cross - industry Application Scenarios

- Medical Field: Surgical forceps and orthopedic implants with a machining accuracy of IT5 level need to meet the ASTM F138 medical stainless - steel standard.

- Energy Equipment: Pump and valve parts in nuclear power plants need to pass a 48 - hour salt - spray test, and the surface roughness should be controlled within Ra0.4μm.

- Semiconductor Manufacturing: Ultra - high - vacuum chambers are made of 316L ultra - low - carbon stainless steel, and the helium leakage rate after welding needs to be lower than 1×10^ - 9 Pa·m³/s.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian