A Comprehensive Analysis Of Metal Forming Processes: Core Technologies And Application Scenarios

Release time:2026-04-22

Visits:103

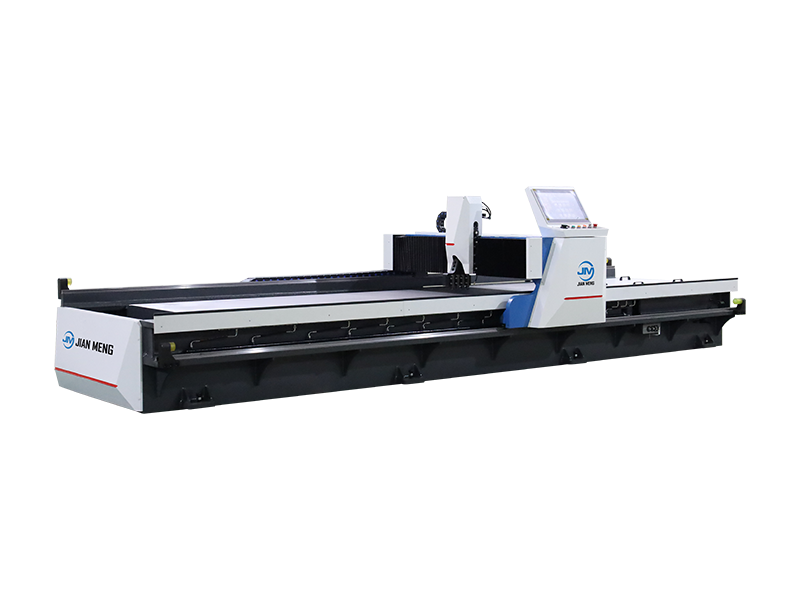

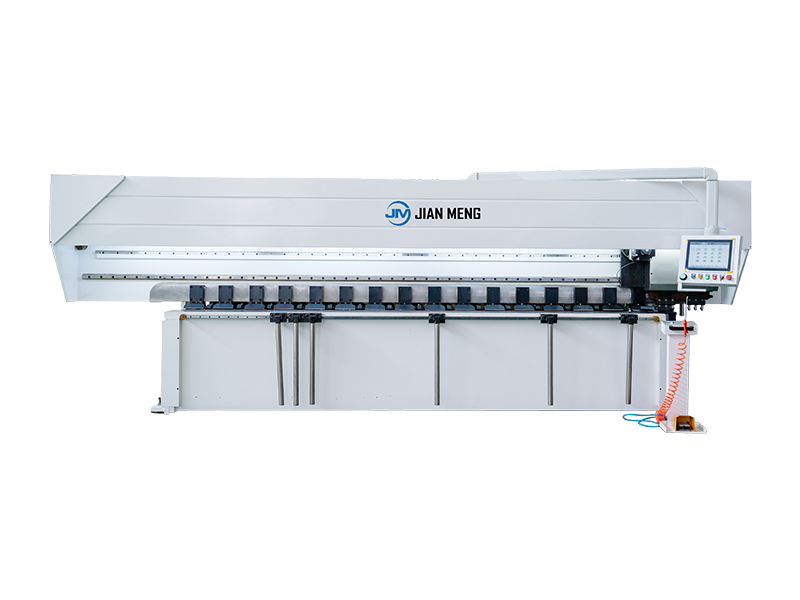

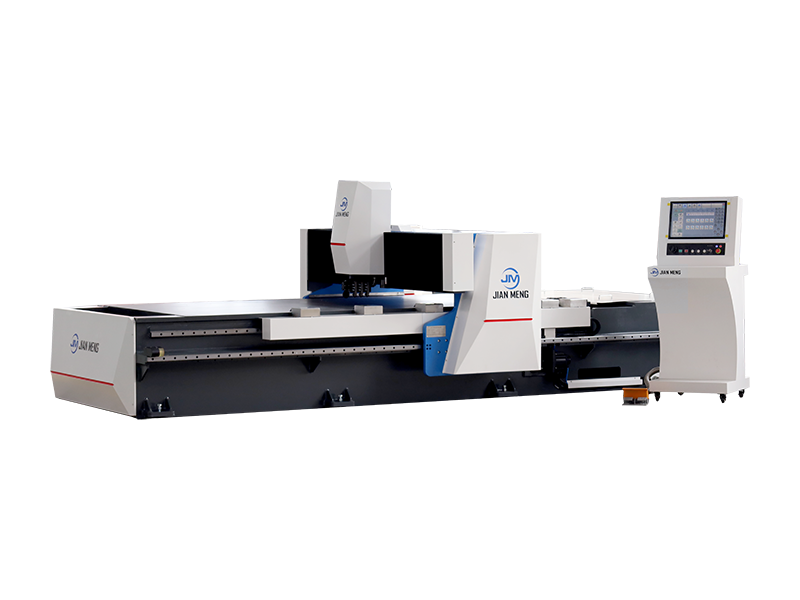

Metal forming is a key technology for manufacturing parts or products by changing the shape, size, and properties of metals through physical or chemical means. It is widely used in industries such as automotive, aerospace, electronics, and construction. This article will systematically sort out the core processes, technical characteristics, and selection principles of metal forming, providing a reference guide for the industry.

Metal forming tools

I. Classification of Main Metal Forming Processes

1. Stamping Forming

Stamping uses dies and presses to perform blanking, bending, or stretching on metal sheets, and is suitable for producing thin - walled parts. Its advantages lie in high efficiency and low cost, and it is commonly used in mass - production scenarios such as automotive body panels and electronic product casings.

2. Forging Forming

Forging causes plastic deformation of metal billets through hammering or pressure and is divided into open - die forging and closed - die forging. Open - die forging is suitable for large and simple parts (such as wind power flanges), while closed - die forging can manufacture complex small parts (such as gears). Forged parts have high strength and impact resistance, making forging the preferred process for high - load components such as engine crankshafts and connecting rods.

3. Casting Forming

Casting involves pouring molten metal into a mold and forming a part after solidification, which can produce parts with complex internal cavity structures (such as engine blocks). Sand casting has low cost and is suitable for single - piece production; precision casting (such as die - casting) has high precision and is used for precision parts such as 3C product casings. However, castings are prone to defects such as pores and shrinkage porosity and require subsequent processing.

4. Powder Metallurgy

Powder metallurgy involves pressing and sintering metal powders into shape, with a material utilization rate of up to 97%. It is suitable for complex structural parts such as oil - impregnated bearings and gears. This process does not require cutting and can directly achieve near - net shaping, with broad application prospects in emerging fields such as humanoid robots.

5. Rolling Forming

Rolling involves rolling metal billets through rolls and is divided into hot rolling (for steel plate production) and cold rolling (for aluminum foil manufacturing). Hot rolling has high efficiency but low precision, while cold rolling can improve surface finish and dimensional accuracy and is the core technology for metal sheet processing.

6. Welding Forming

Welding connects metal components through fusion welding (such as arc welding and laser welding) or pressure welding (such as resistance welding) and is widely used in pipeline and steel structure manufacturing. The new friction stir welding technology can avoid material melting and is suitable for joining high - melting - point alloys such as aluminum alloys.

7. 3D Printing (Additive Manufacturing)

3D printing manufactures parts by layer - by - layer stacking of metal powders or wires, breaking through the geometric limitations of traditional processes. It is suitable for prototyping complex aerospace components and producing personalized medical implants. Current technology is developing towards large - scale and multi - material applications.

II. Core Factors for Process Selection

1. Material Characteristics: Low - melting - point alloys such as aluminum alloys are suitable for die - casting, while high - strength steels are preferably processed by forging.

2. Part Complexity: Parts with complex internal cavities are preferably produced by casting or 3D printing, while simple - structured parts can be formed by stamping.

3. Production Batch: After amortizing the mold cost, stamping/closed - die forging is suitable for large - scale production, while sand casting is suitable for small - batch production.

4. Cost - effectiveness: Powder metallurgy can reduce material waste, and machining can improve the qualification rate of precision parts.

III. Technological Development Trends

Metal forming is evolving towards compounding and intelligentization. Multi - process collaboration (such as casting - forging compounding), digital simulation (for optimized die design), and flexible production lines (with quick - die - change systems) have become the focus of development. The new generation of superplastic forming technology can achieve micron - level precision control and has significant potential in the field of precision electronic component manufacturing.

From basic process innovation to intelligent manufacturing upgrades, metal forming technology continuously drives the transformation of the manufacturing industry. Enterprises need to combine material innovation with process optimization to find the best balance among quality, efficiency, and sustainability to meet the ever - upgrading requirements of the high - end manufacturing field.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian