In manufacturing, metalworking, and precision fabrication, a grooving machine is a specialized material-processing tool designed for controlled, repeatable creation of grooves—narrow channels with defined depth, width, and cross-sectional geometry—in workpieces. Unlike general-purpose cutting tools, grooving machines are engineered to deliver targeted material removal, ensuring grooves meet strict dimensional tolerances (often ±0.01mm for CNC models) and surface finish requirements (Ra 0.8–3.2 μm). These grooves serve critical functional or aesthetic purposes, from enabling mechanical assembly and fluid flow to enhancing structural performance or decorative appeal. Below is a detailed breakdown of its core functions, classifications, industry applications, technical benefits, and selection criteria.

1. Definition & Core Functionalities

At its core, a grooving machine performs precision material removal to form grooves with consistent cross-sections (e.g., V-shape, U-shape, rectangular, or custom profiles). Key functionalities include:

- Controlling groove geometry: Adjusting depth (0.1mm to 50mm+), width (0.5mm to 20mm+), and angle (e.g., 30°, 45°, 60° for V-grooves) to match design specifications.

- Ensuring surface integrity: Minimizing burrs, thermal distortion, or micro-cracking (critical for high-strength materials like titanium or Inconel).

- Enabling repeatability: Producing identical grooves across hundreds or thousands of workpieces (essential for mass production).

Grooves created by these machines fulfill diverse roles:

- Mechanical assembly: Providing seats for O-rings, gaskets, or fasteners (e.g., rectangular grooves in flange joints).

- Fluid management: Creating channels for oil, coolant, or air (e.g., U-shaped grooves in automotive engine blocks).

- Structural enhancement: Reducing material weight while maintaining rigidity (e.g., V-grooves in sheet metal brackets for controlled bending).

- Aesthetic detailing: Forming intricate patterns (e.g., decorative V-grooves in architectural stainless steel panels).

Grooving machines are categorized by operation mode and application focus, each optimized for specific use cases:

| Machine Type | Operational Principle | Key Applications | Precision Range |

|-----------------------------|------------------------------------------------|---------------------------------------------------|-----------------------|

| Manual Bench-Top Groovers | Hand-operated levers or handwheels; manual feed | Small-batch prototyping, hobbyist woodworking, low-tolerance metal parts (e.g., 1mm–2mm grooves in aluminum sheets). | ±0.1–0.5mm |

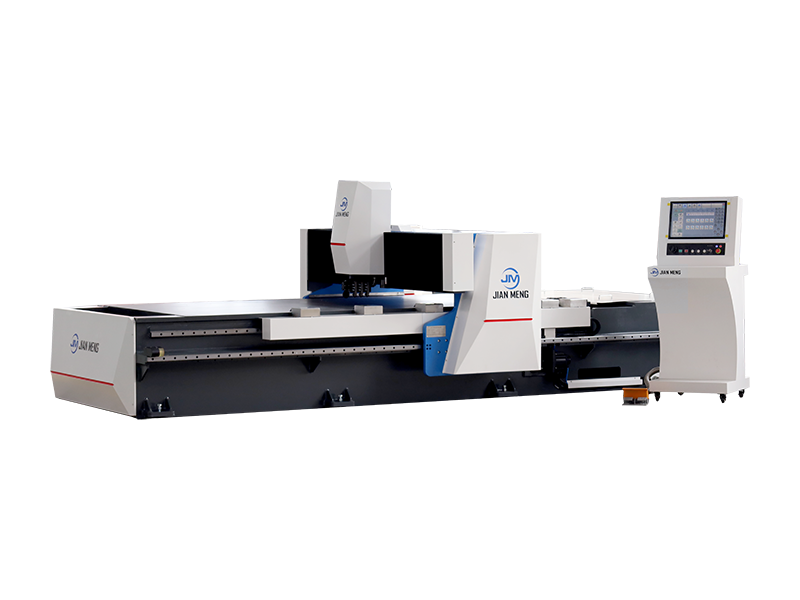

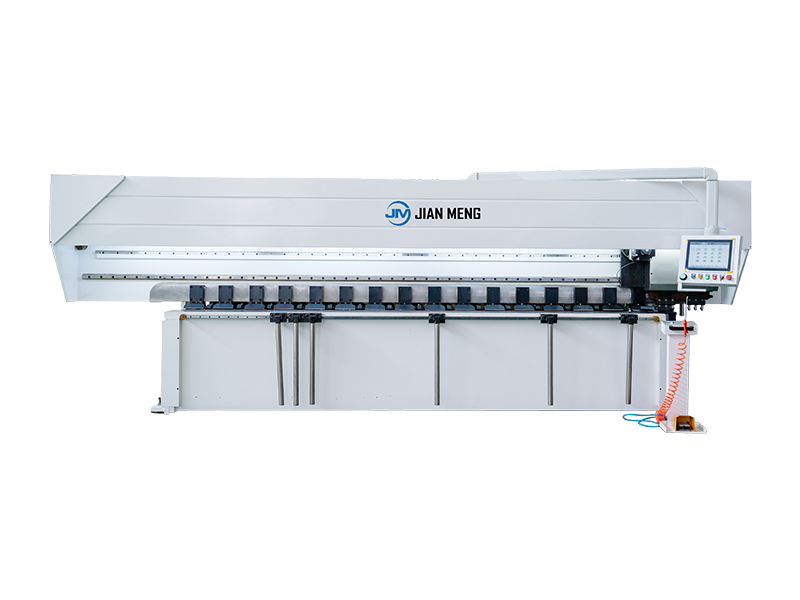

| CNC Sheet Metal V-Groovers | Computerized numerical control; automated feed; carbide-tipped cutters | High-precision sheet metal bending (e.g., 304 stainless steel, 5052 aluminum). Creates V-grooves to enable sharp, crack-free folds. | ±0.01–0.05mm |

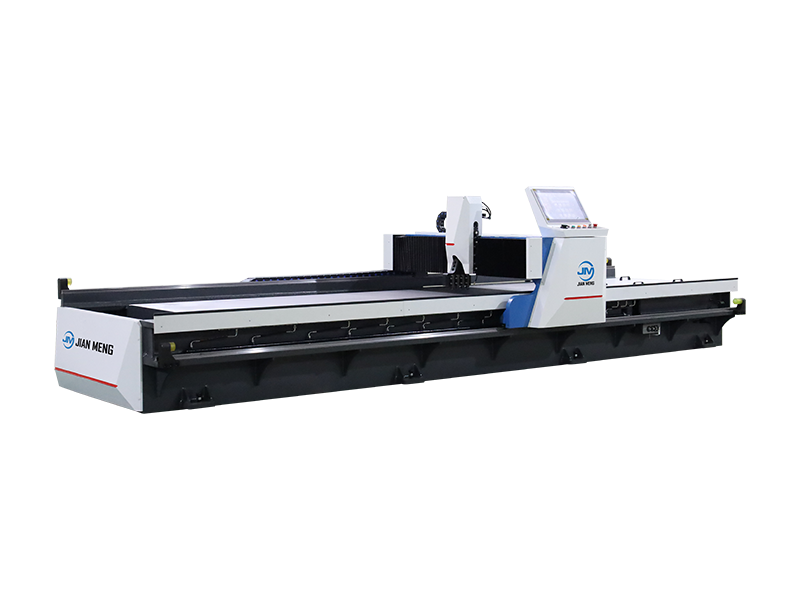

| CNC Rotary Grooving Machines| CNC-controlled spindle; processes cylindrical workpieces (e.g., shafts, pipes) | Automotive transmission components (e.g., synchronizer ring grooves), hydraulic cylinder grooves. | ±0.005–0.02mm |

| Specialized V-Groovers | Dedicated to V-shaped profiles; adjustable angle heads | Architectural metalwork (decorative panels), furniture frames (wood/metal joints), solar panel frame fabrication. | ±0.03–0.1mm |

3. Industry-Specific Applications

Grooving machines are indispensable across sectors, where their precision directly impacts product performance and safety:

3.1 Sheet Metal Fabrication

CNC sheet metal V-groovers are the backbone of this industry. By creating V-grooves (typically 45° or 60°) in metals like aluminum, stainless steel, or galvanized steel, they enable:

- Controlled bending: Grooves reduce material thickness at the bend line, preventing cracking and ensuring consistent fold angles (e.g., 90° bends for electrical enclosures).

- Weight optimization: Removing material in non-critical areas (e.g., V-grooves in HVAC ductwork) without compromising structural strength.

3.2 Elevator & Heavy Machinery

Elevator manufacturers rely on CNC rotary groovers for components like:

- Guide rails: U-shaped grooves that align elevator cars, ensuring smooth vertical movement and reducing friction.

- Traction sheaves: Precision grooves that grip elevator cables, distributing load evenly to avoid cable wear (compliant with EN 81-1 safety standards).

3.3 Automotive & Aerospace

In high-performance industries, grooving machines meet strict tolerance demands:

- Automotive: Creating oil galleries (U-grooves) in engine blocks for coolant flow; forming grooves in brake rotors to dissipate heat.

- Aerospace: Machining V-grooves in titanium alloy brackets (for aircraft wings) to enable lightweight, high-strength assembly; fabricating fuel line grooves with leak-tight tolerances.

3.4 Architecture & Interior Design

Specialized V-groovers are used for decorative and functional purposes:

- Stainless steel cladding: Intricate V-groove patterns that enhance visual texture while hiding fasteners.

- Wooden furniture: Rectangular grooves for drawer slides or dowel joints (e.g., in cabinetry manufacturing).

3.5 Construction

Grooving machines prepare materials for structural integrity:

- Concrete formwork: Creating grooves in steel plates to improve adhesion between concrete and metal.

- Roofing panels: Forming U-grooves in aluminum sheets to channel rainwater away from the building.

4. Technical Benefits of Grooving Machines

Compared to manual cutting or general-purpose mills, grooving machines offer distinct advantages:

4.1 Unmatched Precision & Repeatability

CNC models use servo-driven feeds and high-precision spindles (10,000–20,000 RPM) to maintain groove dimensions within ±0.01mm—critical for industries like aerospace, where even 0.05mm deviations can cause component failure. Manual machines, while less precise, still outperform hand tools for small-batch work.

4.2 Enhanced Efficiency

- Speed: CNC groovers process 3–5x faster than manual methods (e.g., 100+ sheet metal panels per hour vs. 20–30 by hand).

- Automation integration: CNC models can connect to MES (Manufacturing Execution Systems) for real-time production tracking, reducing downtime.

4.3 Material Versatility

Grooving machines handle diverse materials by adapting tooling:

- Metals: Steel (mild, stainless, high-strength), aluminum, copper, titanium, and alloys (use carbide-tipped or CBN tools).

- Non-metals: Wood, plastic (PVC, acrylic), and composite materials (use HSS or diamond-coated tools).

4.4 Reduced Waste & Cost

Precision cutting minimizes scrap (typically <2% for CNC vs. 5–10% for manual methods). Additionally, consistent groove quality reduces rework costs—critical for high-value components like aerospace parts.

5. Key Criteria for Selecting a Grooving Machine

To choose the right machine, align technical specifications with application needs:

5.1 Material Compatibility

- Hardness: For metals with HRc >30 (e.g., tool steel), select CNC models with high-torque spindles and carbide tools.

- Thickness/Size: Sheet metal V-groovers handle 0.5mm–10mm thick sheets; rotary groovers process cylindrical workpieces up to 200mm in diameter.

5.2 Precision Requirements

- High-tolerance applications (aerospace, automotive): Opt for CNC models with linear guides (for feed accuracy) and spindle runout <0.003mm.

- Low-tolerance projects (hobbyist, small-batch woodworking): Manual bench-top machines suffice.

5.3 Production Volume

- High-volume (1,000+ parts/month): CNC machines with automatic tool changers and material loaders.

- Low-volume (1–100 parts/month): Manual or semi-automatic models to avoid overinvesting.

5.4 Total Cost of Ownership (TCO)

- CNC machines have higher upfront costs ($10,000–$100,000+) but lower labor and scrap costs over time.

- Manual machines ($500–$5,000) are cheaper initially but require more operator time and may incur higher rework costs.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian