Comprehensive Analysis Of Forming Machines: Core Types, Working Principles, And Technological Applications

Release time:2025-10-12

Visits:157

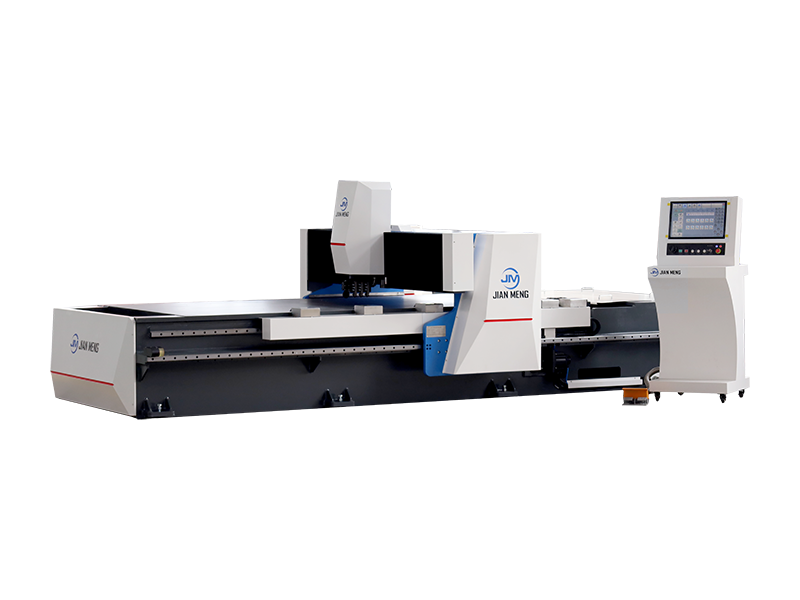

As a core device in modern industry, the forming machine can efficiently process materials into specific shapes through automated processes and is widely used in fields such as packaging, manufacturing, and medicine. Its diverse models, precise working principles, and intelligent design make it a key tool for improving production efficiency.

I. Core Classification of Forming Machines

Forming machines can be classified into carton forming machines, paper box forming machines, case packers, cartoners, etc. according to product series to meet different packaging form requirements. For example, carton forming machines are specialized in batch - completing processes such as box opening, bottom folding, and tape sealing, while cartoners are suitable for high - precision packaging in industries such as pharmaceuticals and food.

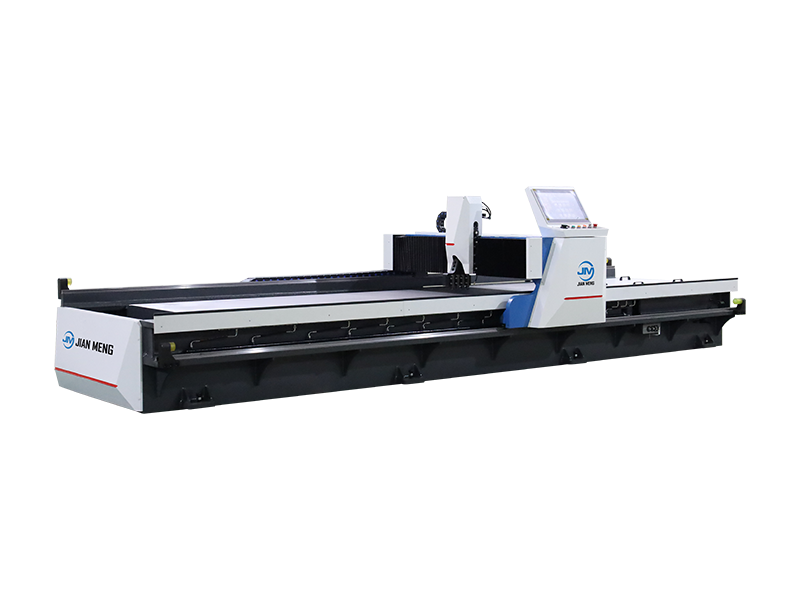

According to the degree of automation, they are divided into semi - automatic and fully automatic models. Semi - automatic equipment requires manual assistance for adjustment and is suitable for small and medium - scale production. Fully automatic models, such as fully automatic carton forming machines, integrate functions such as box suction, forming, and bottom sealing, support assembly line operations, and are suitable for large - scale industrial scenarios.

II. Core Technical Principles and Structural Design

The core operation of the forming machine relies on the collaboration of the mechanical structure, hydraulic system, and intelligent control unit. Taking the injection molding machine as an example, its working process is similar to that of a syringe: molten plastic is injected into the mold through a screw or plunger and then formed after cooling and solidification. The entire process covers multiple - step cycles such as quantitative feeding, melting and plasticizing, mold filling and cooling to ensure high precision and consistency.

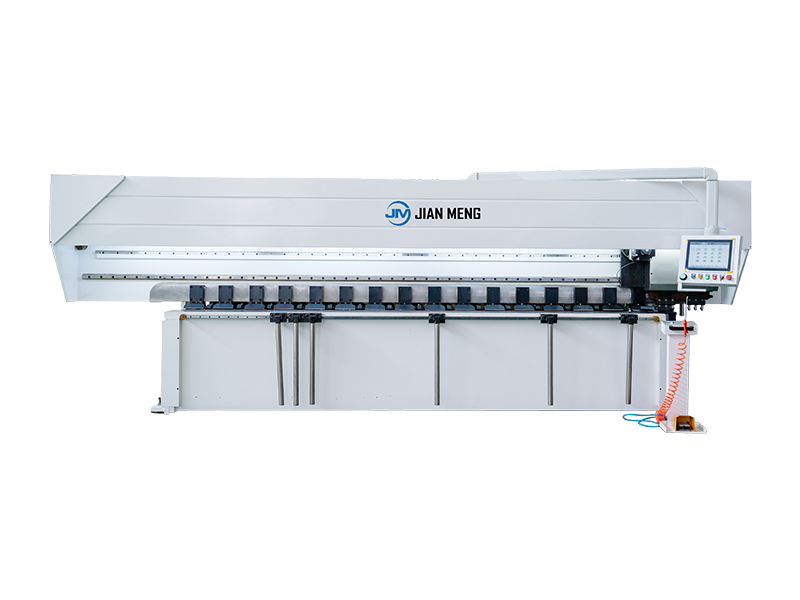

The hydraulic system adopts a dual - pump design: a high - pressure, small - flow pump is used to provide the pressure required for forming, while a low - pressure, large - flow pump realizes rapid filling, taking into account both efficiency and energy consumption. Structurally, the equipment is usually equipped with a high - performance PLC control system and a liquid - crystal interactive interface, integrating functions of self - diagnosis of faults and real - time error correction to reduce the complexity of operation. In addition, the vertical material storage design supports non - stop material replenishment, and only 1 - 2 minutes of manual adjustment is required when switching specifications, significantly improving production continuity.

III. Performance Advantages and Industry Applications

The technological highlights of modern forming machines include:

1. High - efficiency and stability: Precise transmission components ensure low - vibration operation and extend the service life of the equipment.

2. Flexible adaptation: It supports customization of tape folding corner length (50 - 100mm) to meet diverse packaging needs.

3. Intelligent control: The combination of PLC and the human - machine interface enables parameter visualization and rapid debugging.

4. Energy - saving and environmental protection: Stepless hydraulic frequency modulation technology optimizes energy utilization and reduces carbon emissions.

In industries such as food, medicine, and electronics, forming machines can complete the full - process automation from box opening, forming to box sealing, especially suitable for large - batch packaging of standardized products. For example, fully automatic carton forming machines can be seamlessly connected to the assembly line, processing dozens of boxes per minute and significantly reducing labor costs.

IV. Future Development Trends

With the advancement of Industry 4.0, forming machines are developing towards higher intelligence and greening. For example, Internet of Things technology will enable remote monitoring and predictive maintenance of equipment; new material processing technologies can expand the application of equipment in the new energy field; modular design supports rapid reconfiguration of production lines to meet personalized production needs. In addition, driven by environmental protection regulations, low - energy - consumption and low - noise equipment will become the mainstream in the market.

The continuous innovation of

forming machines not only improves the level of industrial automation but also provides a reliable solution for enterprises to reduce costs and increase efficiency. From basic principles to cutting - edge technologies, the evolution of this equipment confirms the dual pursuit of efficiency and sustainability in modern manufacturing.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian