Analysis Of The Classification And Application Fields Of Common Metal Plates

Release time:2025-11-19

Visits:110

As a basic material in the fields of modern industry and architecture, metal plates have become key materials in industries such as building structures, decoration, and machinery manufacturing, thanks to their excellent physical properties and flexible workability. The following systematically analyzes the functions and values of mainstream metal plates from three dimensions: classification, characteristics, and core applications.

I. Classification Standards of Metal Plates

1. Classified by thickness: They are divided into thin plates (0.2 - 4mm), medium plates (4 - 20mm), thick plates (20 - 60mm), and extra - thick plates (>60mm), meeting the strength requirements of different scenarios.

2. Classified by production process: It includes hot - rolled plates (rolled at high temperature with high strength) and cold - rolled plates (with a delicate surface and high precision).

3. Classified by surface treatment: Galvanized plates (for anti - corrosion), tin - plated plates (specially used for food packaging), color - coated plates (with decorative coatings), composite plates (composed of multiple layers of materials), etc.

4. Classified by purpose: It covers more than ten types of specialized products such as building structural plates, automobile steel plates, boiler plates, and electrical silicon steel plates.

II. Application Scenarios of Mainstream Metal Plates

1. Building and Structural Plates

- Color - coated steel plates: Widely used in the roofs and walls of steel - structure factories, airport hangars, with both wind - proof and water - proof functions. The surface coating can be customized in color to enhance aesthetics.

- Corrugated steel plates: The corrugated design enhances the load - bearing capacity, making them suitable for the roofs and partition walls of large facilities such as highway service areas and port terminals.

- Aluminum - magnesium alloy plates: Due to their light weight and high strength, they are commonly used in curtain walls and ceiling decorations. For example, aluminum gusset plates can resist a humid environment and are often used in kitchen and bathroom ceilings.

2. Industrial Manufacturing Plates

- Tin - plated plates: With strong corrosion resistance, more than 90% are used in packaging containers such as food cans and beverage cans, and are also applied to the linings of chemical equipment and the casings of electronic components.

- Electrolytic plates: They play an important role in the fields of medical equipment and precision instruments. Through electrochemical treatment, they achieve high surface cleanliness and corrosion resistance.

- Nickel plates and spring steel plates: Nickel plates are used to manufacture high - temperature - resistant components such as turbine blades and crankshafts; spring steel plates are used in automobile suspension systems, with high elasticity and fatigue resistance.

3. Decorative and Special Plates

- Mirror - finished stainless steel plates: A highly reflective surface is formed through polishing, making them suitable for the column decorations of high - end shopping malls and hotels, with both fire - proof and durability features.

- Aluminum - plastic composite plates: The composite structure of metal and plastic achieves sound and heat insulation, and they are often used as the base materials for building exterior walls and advertising signs.

III. Core Advantages of Metal Plates

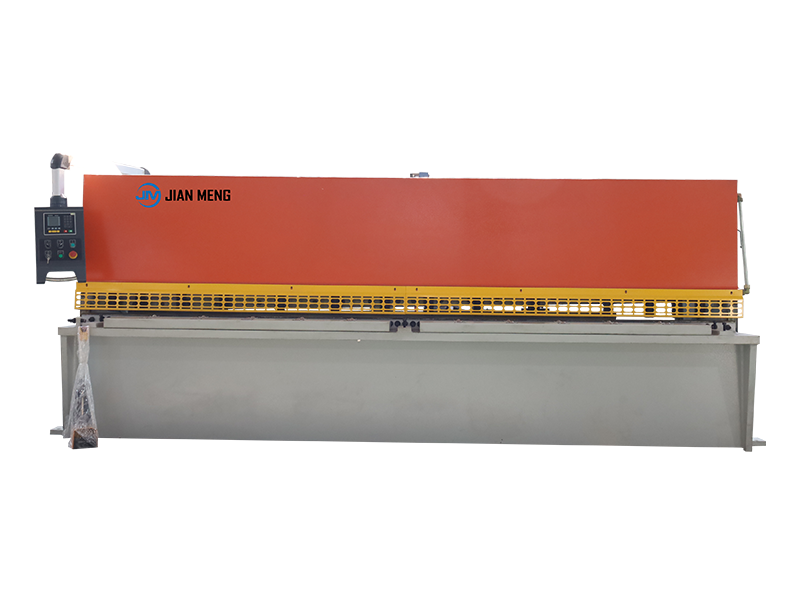

1. Flexible workability: They can be made into complex components through processes such as shearing, stamping, and welding, such as automobile body components or aviation fuel tanks.

2. High coverage and adaptability: Wide - width plates can quickly cover large - area regions. For example, when single steel plates are spliced for the roof of a large - scale warehouse, the construction efficiency is increased by more than 50%.

3. Economy and durability: Taking galvanized plates as an example, their service life can reach 20 - 30 years, significantly reducing the building maintenance cost.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian