A Comprehensive Analysis Of Equipment Polishing Technology: Steps, Methods, And Application Guide

Release time:2026-02-04

Visits:101

Equipment polishing is a crucial process for improving surface finish and aesthetics through mechanical, chemical, or electrochemical means. Its applications cover multiple fields such as metals, plastics, and stones. A reasonable polishing process can not only enhance the appearance quality but also improve corrosion resistance and extend the service life. The following systematically outlines the core points of polishing technology from steps, methods to precautions.

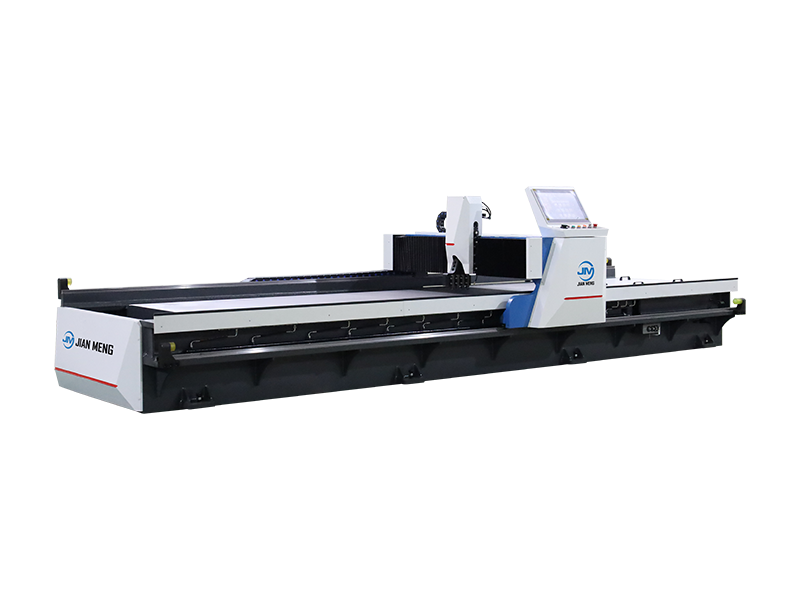

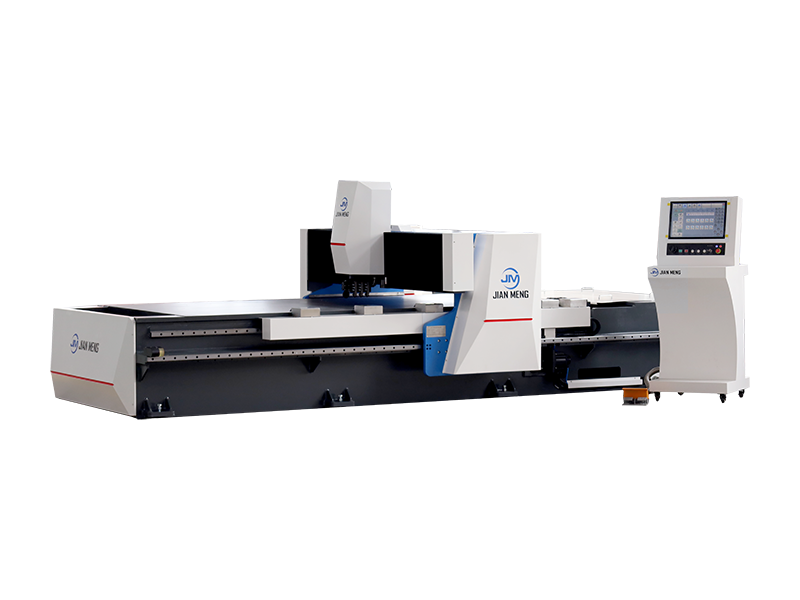

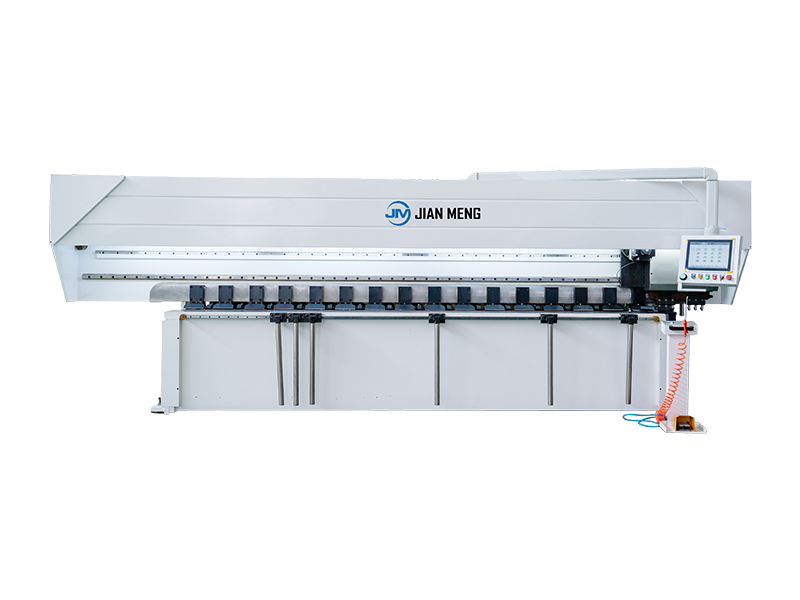

Deburring Polishing Machine

I. Core Steps of Equipment Polishing

1. Surface Pretreatment

Thoroughly clean impurities such as oil stains and rust on the surface to ensure that the polishing surface is clean and pollution - free, laying a foundation for subsequent processes.

2. Graded Polishing

- Rough Polishing: Use coarse - grained abrasives (such as 10 - 20μm Al₂O₃ or Cr₂O₃ suspension) and hard polishing wheels to quickly remove macroscopic scratches and unevenness.

- Fine Polishing: Replace with fine - grained abrasives (such as 1 - 5μm micropowder) and soft polishing wheels to gradually reduce the surface roughness.

- Precision Polishing: Use ultra - fine polishing agents (such as nano - grade polishing paste) and high - precision polishing equipment to achieve a mirror finish.

3. Post - treatment and Protection

Rinse the residual polishing agent and dry it thoroughly. Then apply an anti - oxidation coating or protective film to prevent secondary damage.

II. Detailed Explanation of Four Mainstream Polishing Methods

1. Mechanical Polishing

- Process Principle: Eliminate surface protrusions through cutting or plastic deformation, suitable for hard materials such as metals and plastics. Pressure and speed need to be controlled during rough polishing. Ultra - precision lapping and polishing technology can be used for precision polishing, and the surface roughness can reach Ra0.008μm.

- Equipment Selection:

Electric Polishing Machine: High - power, suitable for large workpieces;

Pneumatic Polishing Machine: Lightweight and portable, suitable for small - scale operations;

Ultrasonic Polishing Machine: Uses high - frequency vibration of the polishing liquid, specializing in precision components.

2. Chemical Polishing

- Technical Advantages: No complex equipment is required, and it can process irregularly shaped workpieces in batches. It uses chemical reagents to preferentially dissolve microscopic protrusions, reducing the surface roughness to the 10μm level.

- Key Points: The polishing liquid formula needs to be precisely formulated according to the material to avoid excessive corrosion.

3. Electrolytic Polishing

- Process Upgrade: An electric current is introduced on the basis of chemical polishing to precisely control the dissolution process, improving flatness and gloss uniformity, especially suitable for conductive materials such as stainless steel and aluminum alloy.

4. Composite Polishing Technology

Combines mechanical and chemical methods. For example, the process of "mechanical rough polishing + chemical precision polishing" takes into account both efficiency and quality and is commonly used for high - precision molds and optical components.

III. Operation Specifications and Risk Control

- Parameter Matching: Select the abrasive grain size according to the material hardness (for example, avoid using sandpaper above #1500 for pre - hardened steel); control the polishing time within 3 - 5 minutes to prevent overheating damage.

- Safety Protection: Wear goggles, dust masks, and protective gloves during operation to avoid contact with chemical reagents and high - speed flying objects.

- Equipment Maintenance: Regularly clean the residues on the polishing wheel, check the motor and transmission parts to ensure the stability of the equipment.

IV. Cross - industry Application Scenario Examples

1. Metal Processing Field

Stainless steel equipment and aluminum alloy components can achieve both corrosion resistance and aesthetic improvement through electrolytic polishing; precision molds can reach nanoscale surface accuracy with the help of ultra - precision lapping and polishing technology.

2. Plastic Products Field

Automotive interiors and electronic product casings use mechanical - chemical composite polishing to eliminate injection molding marks and enhance surface texture.

3. Stone and Glass Industry

Marble and granite are polished with multi - stage diamond abrasives to form a high - gloss finish; glass products reduce micro - cracks through chemical polishing and improve light transmittance.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian