In metalworking, selecting the correct forming equipment is not just a matter of efficiency—it directly impacts part precision, material integrity, and long-term project costs. Whether fabricating a small custom bracket (hobbyist) or mass-producing automotive chassis components (industrial), the right tool aligns with your project’s technical requirements (material, geometry, volume) and operational constraints (budget, space, skill level). This guide provides a structured, technical framework for evaluating forming equipment, covering core categories, selection criteria, and application-specific recommendations to ensure informed decision-making.

1. Foundational Context: Metal Forming Processes & Equipment Alignment

Before selecting equipment, it is critical to map your project’s forming process to the right tool. Metal forming relies on plastic deformation (no material removal) and is categorized by workpiece type (sheet, wire, billet) and deformation method. Below is a breakdown of core processes and their associated equipment:

| Forming Process | Definition | Key Equipment Types |

|-----------------------|-----------------------------------------------------------------------------|-------------------------------------------------------------------------------------|

| Sheet Metal Bending | Deforming flat metal sheets (0.1–6 mm thick) along a linear axis to create angles (90°, 135°) or radii. | Press brakes (manual/pneumatic/hydraulic), folding machines, hand seamers. |

| Sheet Metal Forming | Shaping sheets into 3D geometries (e.g., curved panels, enclosures) via stretching/compression. | Roll formers, vacuum forming machines, pneumatic forming presses. |

| Heavy-Duty Forging | Shaping thick-gauge metal (25–100+ mm: billets, bars) via high compressive force (hot/cold). | Hydraulic presses, power hammers (mechanical/hydraulic), forging presses. |

| Wire/Rod Forming | Bending or drawing thin metal wires/rods (0.5–20 mm diameter) into coils, fasteners, or complex shapes. | Wire bending machines, draw benches, spring formers. |

Forming equipment is grouped by scale, power source, and specialization. Below is a detailed breakdown of the most common types, with focus on their technical specs and application fit:

2.1 Hand & Bench-Top Forming Tools (Small-Scale/DIY Projects)

Designed for low-volume, intricate work (1–100 parts) with thin-gauge metals (0.1–3 mm). Ideal for hobbyists, small workshops, or on-site repairs.

| Tool Type | Technical Specs | Ideal Applications |

|--------------------------|---------------------------------------------------------------------------------|-------------------------------------------------------------------------------------|

| Hand Seamers | - Capacity: 0.5–2 mm (aluminum/steel)<br>- Bend angle range: 0–180°<br>- No power required. | Seaming HVAC ducts, bending small sheet metal tabs (e.g., electronics enclosures). |

| Manual Bench Shears | - Cutting capacity: 0.1–3 mm (steel)<br>- Throat depth: 100–300 mm<br>- Mechanical lever operation. | Trimming sheet metal blanks, cutting straight edges for small brackets. |

| Manual Press Brakes | - Bend capacity: 0.5–2 mm (steel)<br>- Maximum bend length: 300–600 mm<br>- Manual crank adjustment. | Bending small parts (e.g., jewelry components, model airplane frames). |

| Sheet Metal Notchers | - Notch depth: 10–50 mm<br>- Capacity: 0.1–2 mm (steel)<br>- Bench-mounted. | Cutting notches for box corners, preparing sheet metal for bending. |

Key Advantage: Low upfront cost ($50–$500), minimal space requirements (fits on standard workbenches), and no power dependency.

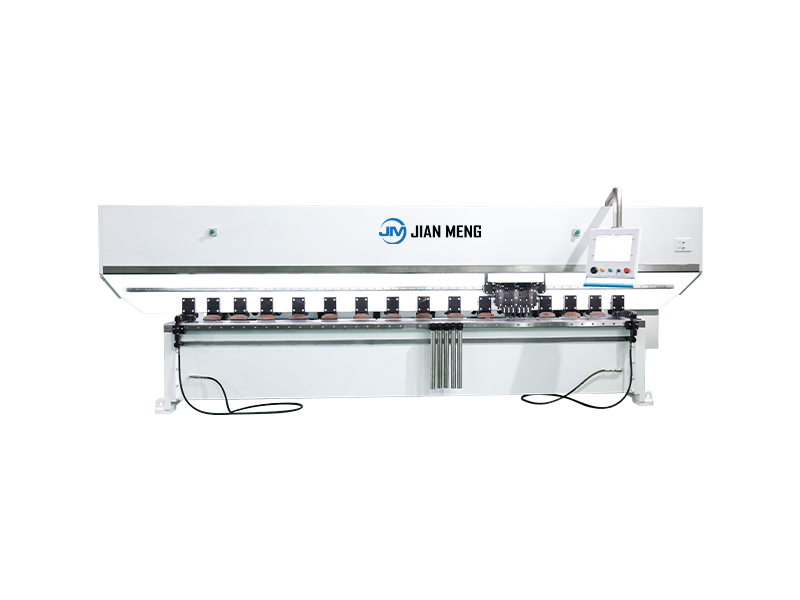

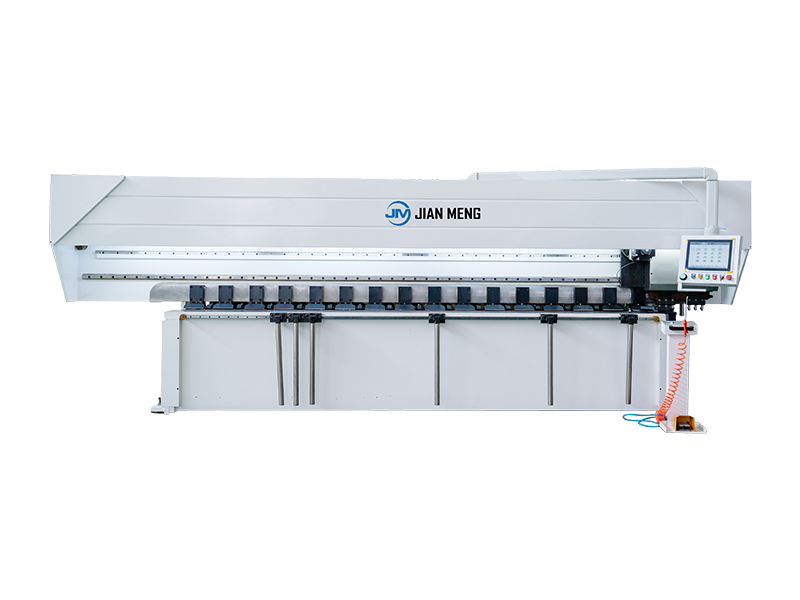

2.2 Power-Driven Sheet Metal Forming Equipment (Medium-Volume Production)

For mid-scale projects (100–10,000 parts) with thin-to-medium gauge metals (0.5–6 mm). Used in automotive aftermarket, HVAC manufacturing, and custom fabrication.

| Tool Type | Technical Specs | Ideal Applications |

|--------------------------|---------------------------------------------------------------------------------|-------------------------------------------------------------------------------------|

| Pneumatic Press Brakes | - Bend capacity: 0.5–4 mm (steel)<br>- Bend length: 600–1,200 mm<br>- Force: 5–20 kN<br>- CNC controls (optional for repeatability). | Mass-producing brackets, bending automotive trim panels, forming HVAC fittings. |

| Roll Formers | - Material thickness: 0.5–3 mm (steel/aluminum)<br>- Profile range: C-channels, U-beams, custom cross-sections<br>- Speed: 5–20 m/min. | Manufacturing long structural components (e.g., roof trusses, shelf brackets), continuous-length parts. |

| Pneumatic Forming Presses | - Force: 10–50 kN<br>- Stroke length: 50–200 mm<br>- Cycle time: 10–30 cycles/min. | Stamping logos into sheet metal, forming shallow 3D parts (e.g., appliance panels, electronic casings). |

Key Advantage: Balances speed (faster than manual tools) and precision (±0.1 mm tolerances), with moderate upfront costs ($2,000–$20,000).

2.3 Heavy-Duty Forming Equipment (Industrial/High-Volume Production)

Engineered for high-volume (10,000+ parts) or heavy-gauge metal (6–100+ mm) applications. Critical for automotive, aerospace, and industrial machinery manufacturing.

| Tool Type | Technical Specs | Ideal Applications |

|--------------------------|---------------------------------------------------------------------------------|-------------------------------------------------------------------------------------|

| Hydraulic Press Brakes | - Bend capacity: 3–25 mm (steel)<br>- Bend length: 1.2–6 m<br>- Force: 50–500 kN<br>- CNC controls (for complex multi-axis bends). | Bending thick automotive chassis components, forming large structural steel panels (e.g., construction beams). |

| Hydraulic Forging Presses | - Force: 100–5,000 kN<br>- Stroke length: 100–500 mm<br>- Hot/cold forging compatible. | Forging engine crankshafts, gear blanks, and heavy machinery parts (e.g., excavator buckets). |

| Continuous Roll Formers | - Material thickness: 1–6 mm (steel)<br>- Speed: 20–50 m/min<br>- Integrated cutting systems (for precise length control). | Mass-producing automotive frame rails, HVAC ductwork, and solar panel mounting brackets. |

Key Advantage: High throughput (up to 1,000 parts/hour), ability to handle thick/high-strength metals (e.g., stainless steel, titanium), and CNC integration for automated production.

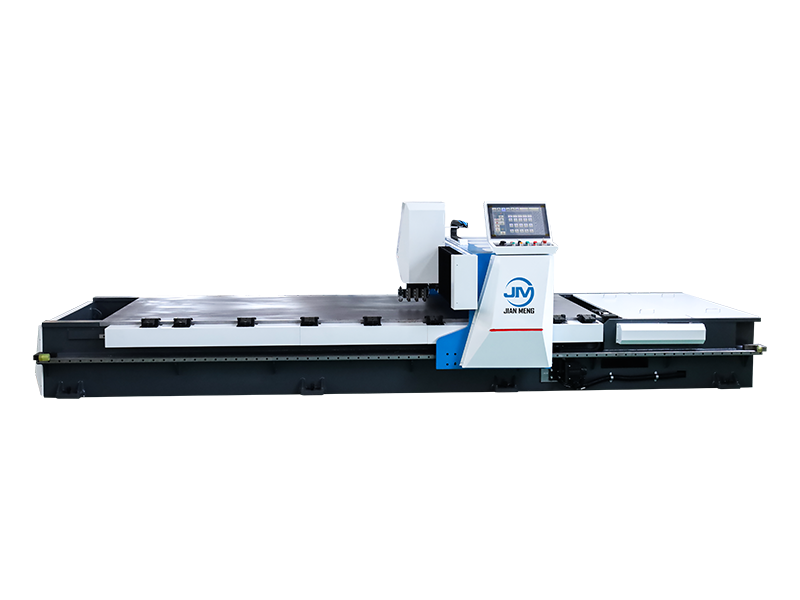

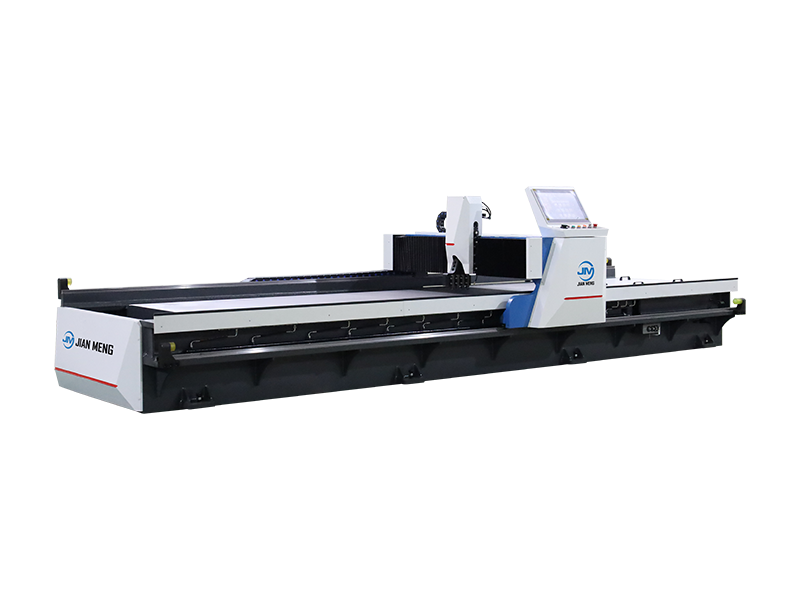

2.4 Universal Forming Machines (Versatile/Mixed-Project Workshops)

All-in-one systems designed to perform multiple forming tasks (bending, cutting, stamping) with minimal tool changes. Ideal for workshops with diverse project needs (e.g., custom fabrication shops, R&D labs).

| Machine Type | Technical Specs | Ideal Applications |

|----------------------------|---------------------------------------------------------------------------------|-------------------------------------------------------------------------------------|

| CNC Universal Forming Centers | - Integrated functions: Bending, punching, shearing<br>- Material capacity: 0.5–6 mm (steel)<br>- CNC programming (for complex part geometries). | Prototyping new parts (e.g., consumer electronics casings), small-batch production of mixed components (brackets, panels, enclosures). |

| Hydraulic Universal Presses | - Force: 20–200 kN<br>- Interchangeable dies (for bending, stamping, pressing)<br>- Adjustable stroke length (0–300 mm). | Forming custom parts with varying geometries (e.g., aerospace prototypes, industrial fasteners), assembling components (e.g., pressing bearings into housings). |

Key Advantage: Reduces equipment footprint (one machine replaces 3–4 specialized tools), lowers setup time for mixed projects, and adapts to changing production needs.

3. Critical Selection Criteria: Technical & Operational Factors

To avoid over-specifying (wasting budget) or under-specifying (compromising quality), evaluate these factors against your project requirements:

3.1 Project Technical Requirements

- Material Specifications:

- Type: Aluminum (softer, requires lower force) vs. steel (harder, needs higher force) vs. titanium (high-strength, requires hydraulic equipment).

- Thickness/Gauge: Thin metals (<3 mm) work with pneumatic/manual tools; thick metals (>6 mm) demand hydraulic equipment.

- Formability: Ductile metals (mild steel, aluminum) are compatible with most tools; brittle metals (cast iron) require specialized forging equipment.

- Part Geometry:

- 2D vs. 3D: Flat bends (2D) use press brakes; curved/complex 3D shapes (e.g., automotive fenders) need roll formers or pneumatic forming presses.

- Tolerance: Tight tolerances (±0.05 mm, e.g., aerospace parts) require CNC-controlled equipment; loose tolerances (±0.5 mm, e.g., HVAC ducts) work with manual/pneumatic tools.

- Production Volume:

- Low Volume (<100 parts): Manual/bench-top tools (cost-effective, minimal setup time).

- Medium Volume (100–10,000 parts): Pneumatic/CNC power tools (balances speed and cost).

- High Volume (>10,000 parts): Hydraulic/automated equipment (maximizes throughput, reduces labor costs).

3.2 Operational Constraints

- Space Availability:

- Bench-top tools: Require 0.5–1 m² of workbench space.

- Power-driven tools (pneumatic press brakes): Need 2–5 m² of floor space.

- Industrial hydraulic presses: Require 10–50 m² (plus clearance for material handling).

- Power & Utility Access:

- Manual tools: No power needed.

- Pneumatic tools: Require compressed air (6–10 bar, 10–50 m³/h).

- Hydraulic/CNC tools: Need 220V/380V electrical power (5–50 kW) and cooling systems (for high-duty cycles).

- Skill Level:

- Manual tools: Minimal training (1–2 hours).

- Pneumatic/CNC tools: Require training on controls/programming (1–2 weeks).

- Industrial hydraulic equipment: Need certified operators (specialized training, 1–3 months).

3.3 Total Cost of Ownership (TCO)

Upfront cost is only one component—TCO includes operating, maintenance, and tooling costs:

- Upfront Cost:

- Manual tools: $50–$500.

- Pneumatic/CNC tools: $2,000–$50,000.

- Industrial hydraulic equipment: $50,000–$500,000+.

- Operating Costs:

- Pneumatic tools: Air consumption (10–50 m³/h, ~$0.50–$2/hour).

- Hydraulic tools: Energy consumption (5–50 kW, ~$1–$10/hour) + hydraulic fluid replacement ($100–$500/year).

- Maintenance Costs:

- Manual tools: Minimal ($10–$50/year for lubrication).

- Power tools: Annual servicing ($500–$5,000/year for CNC/hydraulic systems) + die replacement ($100–$10,000/die, depending on complexity).

Example: A $5,000 pneumatic press brake may cost $1,000/year to operate/maintain, while a $500 manual brake costs $50/year—but the pneumatic model produces 10x more parts per hour, making it cost-effective for medium-volume projects.

4. Application-Specific Equipment Recommendations

To simplify selection, below are tailored recommendations for common project types:

| Project Type | Material/Thickness | Ideal Equipment | Rationale |

|----------------------------|-------------------------------------------------------------------------------------|-------------------------------------------------------------------------------------|---------------------------------------------------------------------------|

| DIY/Hobbyist: Custom Brackets | Aluminum/steel (0.5–2 mm), low volume (<50 parts) | Manual bench shear + manual press brake | Low cost, minimal space, no power needed. |

| HVAC: Ductwork Fabrication | Galvanized steel (0.5–1.5 mm), medium volume (100–500 parts) | Pneumatic seamer + roll former | Fast seaming/rolling, consistent duct cross-sections. |

| Automotive Aftermarket: Custom Fenders | Aluminum (1–3 mm), low-to-medium volume (50–500 parts) | Pneumatic forming press + CNC press brake | Precision bending for complex curves, repeatable results. |

| Industrial: Engine Crankshafts | Alloy steel (50–100 mm), high volume (>10,000 parts) | Hydraulic forging press + automated material handling | High force for hot-forging, automation for high throughput. |

| Aerospace: Titanium Panels | Titanium (2–6 mm), medium volume (100–1,000 parts), tight tolerances (±0.05 mm) | CNC hydraulic press brake + vacuum forming machine | Precise force control, compatibility with high-strength titanium. |

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian