Sheet metal bending is a core metal forming process in manufacturing, enabling the transformation of flat metal sheets into structural components, enclosures, and precision parts across industries such as automotive, aerospace, construction, and electronics. By inducing controlled plastic deformation (without material fracture), bending enhances the rigidity, load-bearing capacity, and functional versatility of sheet metal—making it indispensable for producing components ranging from automotive body panels to aerospace brackets and consumer appliance housings. This guide provides a technical overview of sheet metal bending equipment, their operational principles, application scopes, and actionable insights for selection, maintenance, and safety compliance.

Sheet metal bending relies on the material’s ability to undergo elastic-plastic deformation when subjected to concentrated force. The process involves three key technical parameters:

- Bend Angle: The desired angle between the two folded segments (typically 0°–180°).

- Inside Radius: The radius of the inner curve after bending, determined by material thickness, ductility, and tooling design (smaller radii require higher ductility to avoid cracking).

- K-Factor: A material-specific constant that accounts for the neutral axis shift during bending, critical for calculating accurate bend deductions and ensuring dimensional precision.

The process is governed by the material’s yield strength and tensile strength—harder materials (e.g., high-strength steel) require higher bending forces, while ductile materials (e.g., aluminum, copper) accommodate tighter radii and complex bends.

Classification of Sheet Metal Bending Equipment

Sheet metal bending equipment is categorized by automation level, tooling design, and application capacity. Below is a structured breakdown of industry-standard equipment types:

1. Manual Bending Equipment

- Structural Design: Compact, hand-operated tools with a fixed frame, pivot points, and manual force application (via levers or screws).

- Key Types:

- Manual Folder Benders: Ideal for thin-gauge sheets (0.5–3 mm) of aluminum, copper, or mild steel. Used for simple bends (90° angles, hems) in small workshops or prototyping.

- Handheld Bending Bars: Portable tools for on-site bending of light-gauge metal (e.g., HVAC ductwork, sheet metal flashing).

- Advantages: Low cost, minimal space requirements, easy operation.

- Limitations: Limited to low-volume, low-force applications; precision dependent on operator skill.

2. Semi-Automatic Bending Equipment

- Structural Design: Combines manual setup with powered force application (pneumatic or hydraulic drives). Features adjustable tooling and basic digital controls for angle setting.

- Key Types:

- Semi-Automatic Press Brakes: Equipped with a hydraulic/pneumatic ram, fixed punch, and adjustable die. Suitable for medium-gauge sheets (3–10 mm) and moderate production volumes.

- Foot-Operated Benders: Use foot pedals to actuate bending force, freeing hands for material positioning. Common in small-batch manufacturing of brackets, frames, and panels.

- Advantages: Higher force capacity than manual tools; improved repeatability; lower operator fatigue.

- Limitations: Less efficient for complex bends; setup time longer than fully automated systems.

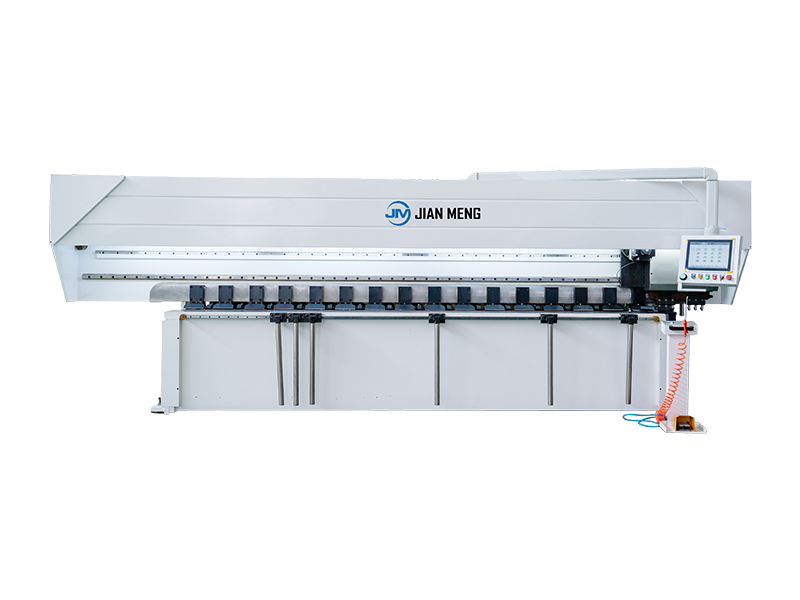

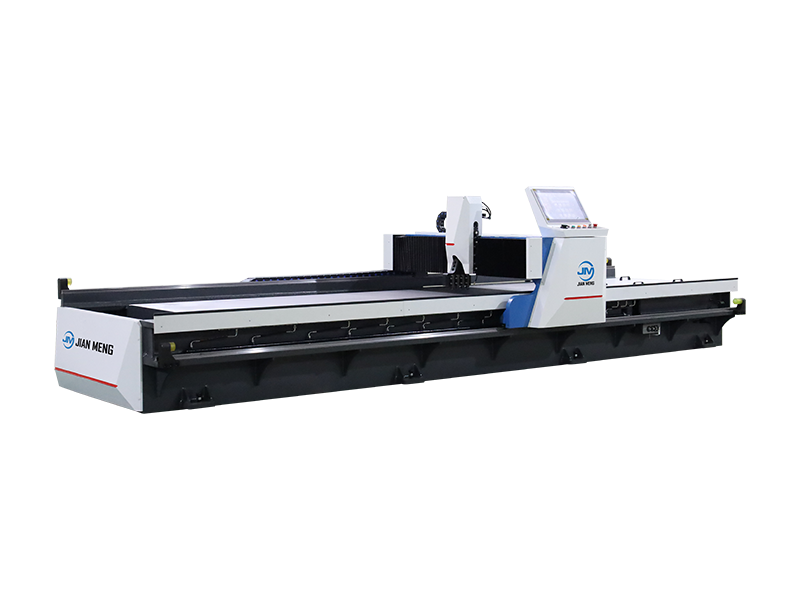

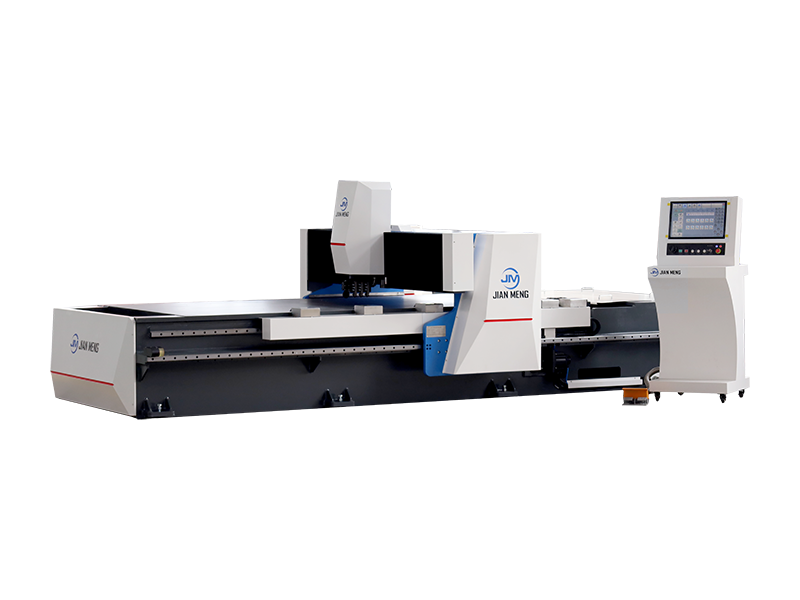

3. Fully Automatic CNC Bending Equipment

- Structural Design: Computer Numerical Control (CNC)-integrated systems with servo-electric or hydraulic drives, precision tooling, and advanced software for programming complex bends.

- Key Types:

- CNC Press Brakes: The industry standard for high-precision, high-volume production. Equipped with multi-axis controls (X, Y, Z, R, C axes) for complex bends (e.g., offset bends, compound angles) and tight tolerances (±0.1° angle accuracy).

- CNC Folding Machines: Use clamping bars and folding beams to produce consistent bends in thin-to-medium gauge sheets (0.8–6 mm). Ideal for aerospace and electronics components requiring high repeatability.

- Advantages: Unmatched precision, fast setup times, ability to handle complex geometries; compatible with CAD/CAM software for seamless workflow integration.

- Limitations: Higher initial investment; requires trained operators for programming and maintenance.

4. Specialized Bending Equipment

- Bending Presses (Hydraulic/Mechanical): Heavy-duty machines for thick-gauge sheets (10–50 mm) and high-strength metals (e.g., stainless steel, structural steel). Use punch-and-die tooling to form complex shapes (e.g., U-channels, I-beams) in construction and heavy machinery manufacturing.

- Telescopic Benders: Designed for long-length or large-radius bends (e.g., pipes, tubes, and curved sheet metal components). Common in automotive exhaust systems and architectural metalwork.

- Panel Benders: Specialized CNC machines for bending large, flat panels (e.g., appliance housings, control cabinets) with minimal material distortion. Feature automated clamping and folding to ensure edge straightness.

Critical Equipment Selection Criteria

Selecting the right bending equipment requires aligning technical specifications with application requirements. Key factors to consider:

1. Material Characteristics

- Material Type: Ductile materials (aluminum, brass) work with manual/semi-automatic equipment; high-strength steel or thick-gauge sheets (>10 mm) require hydraulic CNC press brakes or bending presses.

- Thickness & Yield Strength: Calculate required bending force using the formula: \( F = \frac{K \times S \times t^2 \times L}{W} \) (where \( K \) = material factor, \( S \) = yield strength, \( t \) = sheet thickness, \( L \) = bend length, \( W \) = die width). Ensure the equipment’s force capacity (measured in tons) exceeds the calculated value.

2. Precision & Geometric Requirements

- Tolerance Needs: Aerospace or electronics components (tolerance ±0.05°) require CNC press brakes with multi-axis controls; general manufacturing (tolerance ±0.5°) can use semi-automatic equipment.

- Bend Complexity: Simple 90° bends suit manual/semi-automatic tools; compound angles, nested bends, or 3D geometries demand CNC systems with CAD/CAM integration.

3. Production Volume & Efficiency

- Low-Volume/Prototyping: Manual or semi-automatic equipment minimizes upfront costs and setup time.

- High-Volume Mass Production: CNC bending machines reduce cycle times (10–60 bends per minute) and ensure consistent quality across batches.

- Changeover Frequency: CNC systems with quick-change tooling are ideal for frequent product switches; dedicated semi-automatic tools suit long-run production of single-part types.

4. Cost-Benefit Analysis

- Initial Investment: Manual tools ($500–$5,000) < semi-automatic ($5,000–$50,000) < CNC ($50,000–$500,000).

- Operational Costs: CNC machines reduce labor costs (one operator handles multiple machines) but require higher maintenance; manual tools have lower maintenance costs but higher labor input.

- Lifespan & Resale Value: CNC equipment (15–20-year lifespan) retains resale value better than manual tools (5–10-year lifespan).

Maintenance & Safety Best Practices

1. Equipment Maintenance

- Routine Inspections: Conduct weekly checks for tooling wear (punch/die damage, surface scratches), hydraulic/pneumatic leaks, and lubrication levels.

- Precision Calibration: Calibrate CNC controls and angle sensors monthly using laser alignment tools to maintain tolerance accuracy.

- Tooling Care: Clean punch/die surfaces after each use; apply anti-corrosion coatings for steel tooling; replace worn tooling when bend quality degrades (e.g., inconsistent angles, material cracking).

- Lubrication: Use manufacturer-recommended lubricants for moving parts (e.g., hydraulic oil for rams, grease for pivot points) at specified intervals (every 250 operating hours).

2. Safety Compliance

- Lockout-Tagout (LOTO): Implement LOTO procedures to isolate power sources during maintenance or tooling changes.

- Personal Protective Equipment (PPE): Mandate safety glasses, cut-resistant gloves, steel-toe boots, and hearing protection (for hydraulic/pneumatic machines) to prevent injuries from metal fragments or noise (85+ dB).

- Operator Training: Ensure operators are certified in equipment-specific procedures, including CNC programming, tooling setup, and emergency shutdown protocols.

- Safety Guards: Maintain intact safety shields for punch/die areas; never bypass interlocks or safety sensors.

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian