What Is A Grooving Machine Used For?

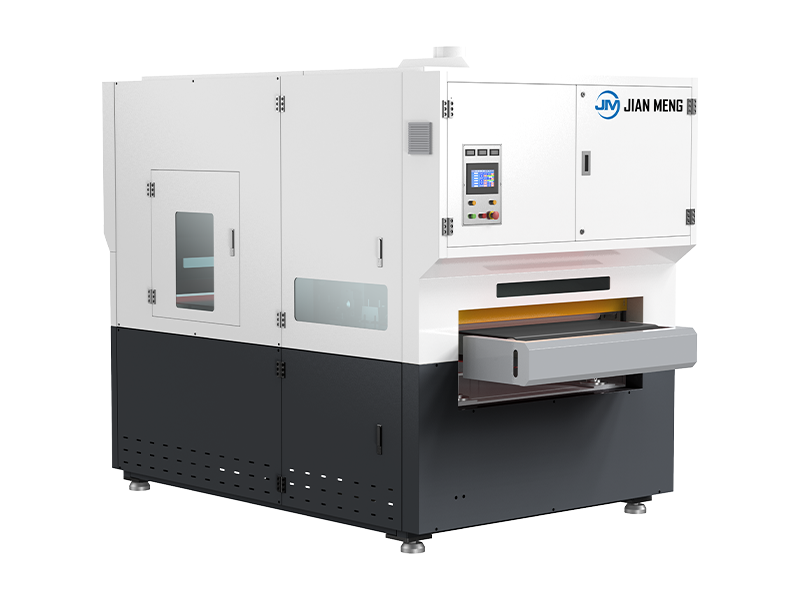

In manufacturing, metalworking, and precision fabrication, a grooving machine is a specialized material-processing tool designed for controlled, repeatable creation of grooves—narrow channels with defined depth, width, and cross-sectional geometry—in workpieces. Unlike general-purpose cutting tools, grooving machines are engineered to deliver targeted material removal, ensuring grooves meet strict dimensional tolerances (often ±0.01mm for CNC models) and surface finish requirements (Ra 0.8–3.2 μm). These grooves serve critical functional or aesthetic purposes, from enabling mechanical assembly and fluid flow to enhancing structural performance or decorative appeal. Below is a detailed breakdown of its core functions, classifications, industry applications, technical benefits, and selection criteria.

1. Definition & Core Functionalities

At its core, a grooving machine performs precision material removal to form grooves with consistent cross-sections (e.g., V-shape, U-shape, rectangular, or custom profiles). Key functionalities include:

- Controlling groove geometry: Adjusting depth (0.1mm to 50mm+), width (0.5mm to 20mm+), and angle (e.g., 30°, 45°, 60° for V-grooves) to match design specifications.

- Ensuring surface integrity:...

2026-01-02

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian