Evolution Of Metal Processing And Manufacturing Technology: Analysis Of Core Processes And Outlook On Future Trends

Metal processing and manufacturing is a process of transforming metal raw materials into products with specific shapes, properties, and functions through a series of technical means. This field encompasses core processes such as casting, forging, welding, heat treatment, and machining, and is continuously iterating and upgrading towards intelligence and green development. The following analysis is carried out from three aspects: technical characteristics, application scenarios, and development trends.

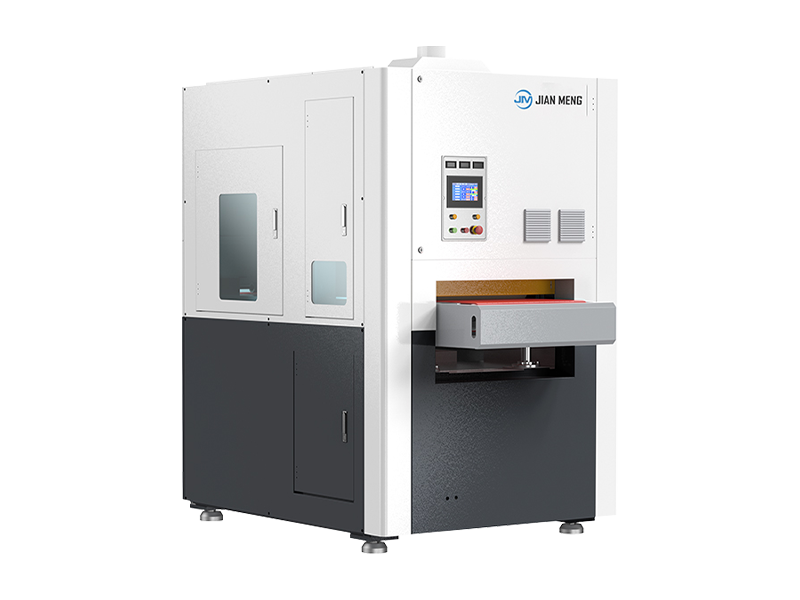

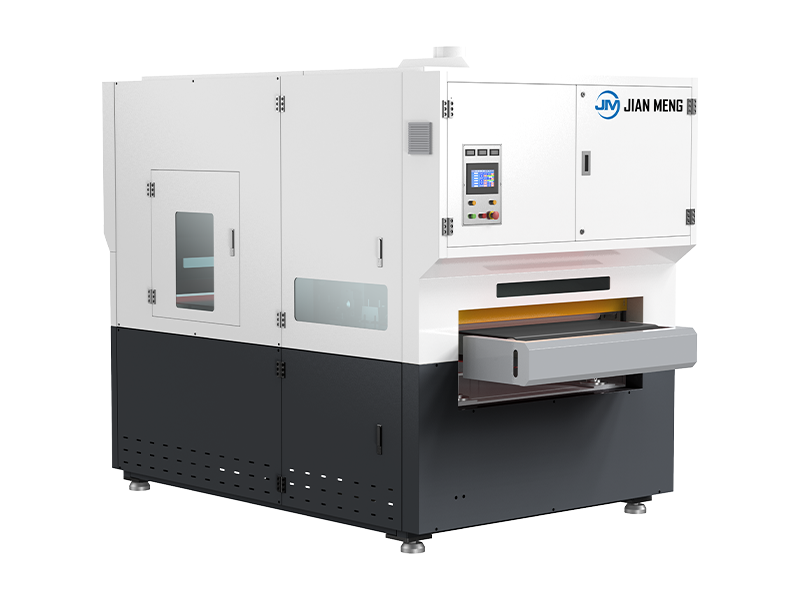

Metal edge rounding and deburring

I. Technical Characteristics and Applications of Core Processes

1. Casting Technology

Casting involves melting metal and injecting it into a mold for shaping, which is suitable for the large - scale production of components with complex shapes and has significant cost advantages. In recent years, innovative methods such as powder metallurgy rheological manufacturing technology have been introduced into the casting field. For example, the rheological forming technology of cermet composites effectively solves the problem of manufacturing large - sized components. By precisely controlling the composite ratio of metal and ceramic, this type of technology can combine the high hardness and toughness of the materials, and is widely used in aerosp...

2025-12-24

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian