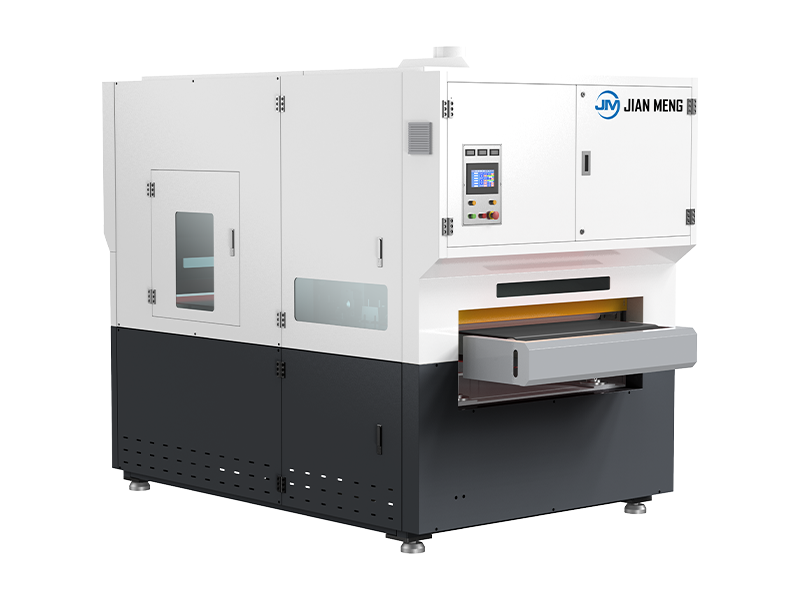

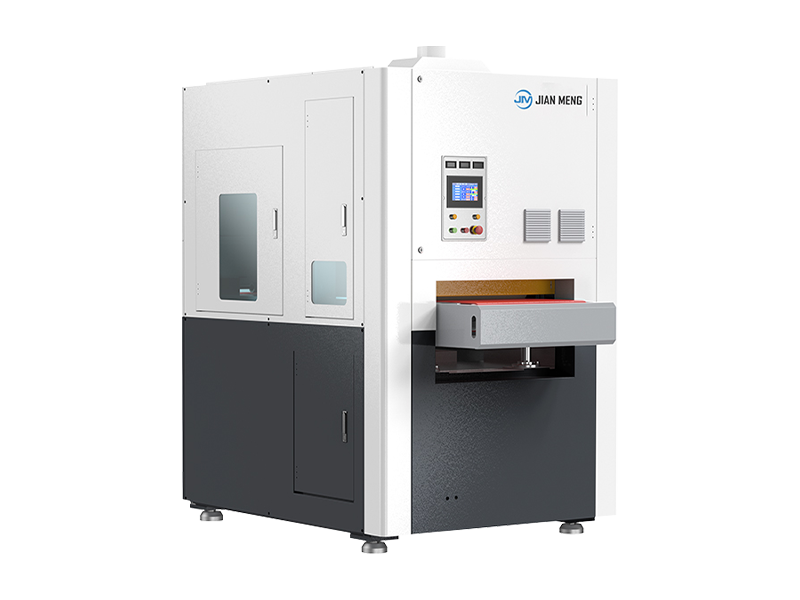

How Deburring Machines Work For Deburring & Edge Rounding

In precision manufacturing—from automotive component production to aerospace part fabrication—burrs (small, jagged material protrusions formed during machining, cutting, or stamping) pose critical risks: they compromise part fit, damage mating components, and create safety hazards for operators. Deburring machines automate the removal of these burrs while often integrating edge rounding (creating controlled, smooth radii on part edges) to meet functional and regulatory standards (e.g., ISO 13715 for edge quality). This guide explains the technical principles of deburring machines, their core operating mechanisms, types, and how they deliver consistent, repeatable results for diverse manufacturing applications.

1. Foundational Context: What Are Burrs, and Why Do They Matter?

Before diving into machine mechanics, it is critical to understand the problem deburring machines solve. Burrs form when machining processes (e.g., laser cutting, milling, drilling) exceed a material’s yield strength, causing plastic deformation at the cut edge. There are three primary burr types, each requiring targeted removal strategies:

- Poisson Burrs: Formed when material is compressed (e.g., punching sheet metal), pushing material outward at the cut edge.

- Tear Burrs: Occur w...

2025-11-07

English

English  中文

中文  Arabic

Arabic  Russian

Russian  Spanish

Spanish  Portuguese

Portuguese  French

French  German

German  Hindi

Hindi  Thai

Thai  Vietnamese

Vietnamese  Khmer

Khmer  Italian

Italian  Turkish

Turkish  Korean

Korean  Belarusian

Belarusian